ULT LIQUID COOLER

A wide operating temperature range is available across the product line — from low-capacity units to high-power machines. There are two types of systems: Machines with an option for indoor or outdoor installation, featuring an integrated internal heat exchanger (CWT). High-capacity units equipped with an external heat exchanger (LNG).

Applications

ULT LIQUID COOLER APPLICATIONS

Lyophilization

Lyophilization, also known as freeze-drying, is a sophisticated dehydration process widely used in pharmaceuticals, biotechnology, and food preservation to extend the shelf life of products while maintaining their structural integrity and bioactivity. This method is particularly valuable for preserving sensitive materials like vaccines, antibiotics, and specialty foods.

LNG Production

Advanced solution precisely engineered for the precooling and liquefaction of biomethane

Chemical Processes

Chemical processes often involve reactions that can be exquisitely sensitive to temperature changes. Cold temperatures play a crucial role in many of these processes by slowing down reaction rates, thus offering greater control over the reaction's outcome. This is particularly important in reactions that are highly exothermic, where excessive heat can lead to runaway reactions or in processes where selectivity and product purity are paramount. By carefully managing temperatures, chemists can steer reactions to favor the formation of desired products while minimizing side reactions and degradation of sensitive compounds. This level of control is indispensable in the synthesis of complex pharmaceuticals, fine chemicals, and in various analytical procedures where precision and reliability are essential.

Freeze Drying

Freeze drying is a freeze drying process in which water is removed from the product after it has been frozen and placed under vacuum, thus allowing the ice crystals to pass directly from the solid state to the vapour state. The process is based on the physical phenomenon of sublimation, which allows a direct transition from the solid to the liquid state. Lyophilisation is mainly used in pharmaceutical and biotechnological research and the industrial production of cosmetic products or drugs such as tablets but also in the drying of foodstuffs and the preservation of archival materials (i.e. books and documents).

Solvent Recovery

Solvent Recovery is based on the fact that the vapor of a boiling mixture will be richer in low boiling point components such as alcohols, acetones, aliphatic hydrocarbons and, ketones. When the vapor is cooled and condensed, the liquid condensate becomes a valuable product that can be sold back into the industrial marketplace.

A solvent recovery system is the preferred recycling method among many industrial manufacturers since it provides a cost-effective solvent recuperation solution and minimizes adverse environmental effects.

Only natural refrigerant (AIR) is used in multiple stages of the refrigeration process. The ultra-low temperature process is realized with a MIRAI INTEX air cycle refrigeration solution MIRAI Cold.

Process Cooling

Large industrial plants or facilities need to cool their production processes almost all year round. Mirai solution is not only environmentally friendly and free of any F-gases or oils, but it is also extremely efficient. The primary role of cooling systems in industrial refrigeration systems is not only to be extremely efficient, reliable and cost-effective, but also to improve the initial production processes and contribute to environmental protection.

Industrial Cooling Processes

In cooling processes, cold temperatures are essential for efficiently reducing the heat in systems or materials. This is crucial for maintaining optimal operating conditions in machinery, preventing overheating, and preserving the integrity of temperature-sensitive products. Effective cooling ensures longevity and reliability across various applications, from industrial machinery to food preservation.

Blood Plasma Freezing

For demanding processes in the manufacture of pharmaceutical and biotechnological products in the temperature range down to -90 °C.

Retrofitting

Switching to our refrigeration system is remarkably easy and helps you effortlessly comply with the latest F-Gas regulations. Installation efforts are minimal: you simply connect four flanges (two for the secondary working fluid and two for water cooling) and complete the electrical cabling. Achieving top-quality production demands the most sophisticated refrigeration solutions. Don't take unnecessary risks—choose reliability, efficiency, and environmental compliance by upgrading seamlessly to our advanced refrigeration system.

High quality production requires the most sofisticated refrigeration system. Don't take risk and choose the best.

Minimal service requirements

Maintenance costs are kept to a minimum. No refrigerant leakage tests, no refrigerant purchase costs and no refrigerant replenishment. Air is supplied free of charge. Long-life, wear-resistant parts and components ensure a long service life thanks to oil-free operation.

Remote monitoring

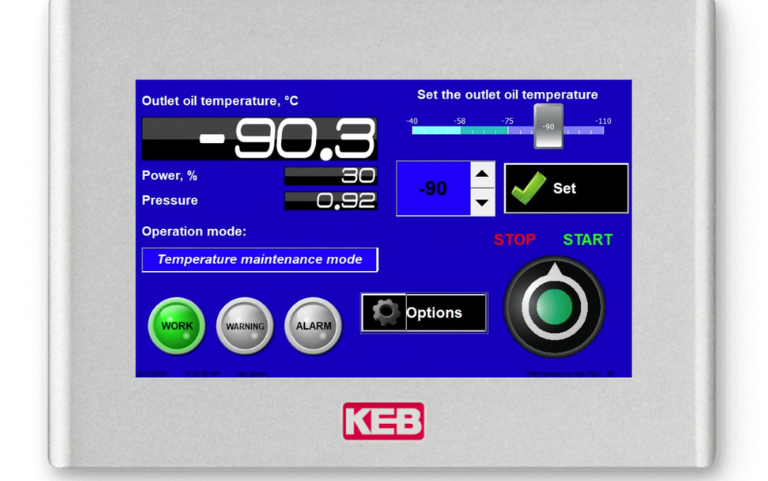

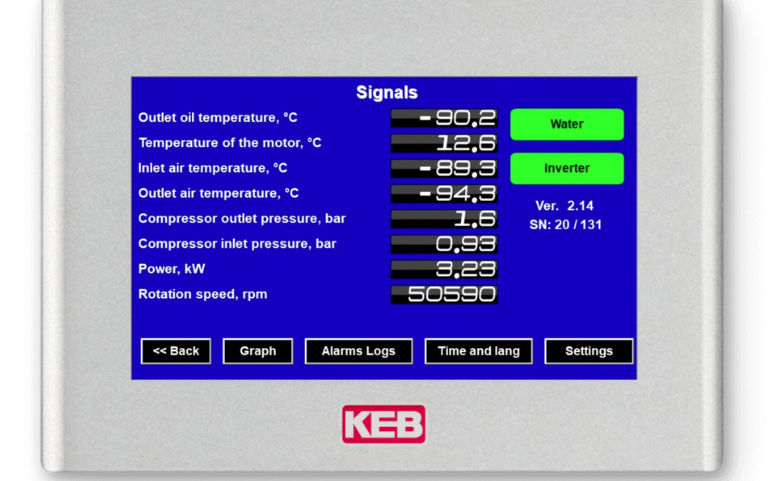

An integrated control system with easy-to-use touchscreen interface and integration of digital communication protocols such as ProfiNET, EtherCAT, EtherNET/IP and Powerlink come as standard.

The system offers real-time monitoring, data archiving and remote monitoring as options. Remote monitoring allows you to check and log machine performance, as well as update machine software online.

The system offers real-time monitoring, data archiving and remote monitoring as options. Remote monitoring allows you to check and log machine performance, as well as update machine software online.

Support from Mirai Intex during machine’s operation and during troubleshooting

Detection and prevention of problems

Regular check-ups of machine condition and performance