Open cycle systems

The open-cycle air cooling system offers a range of products with varying capacities and comes in two configurations: air-cooled (O/A) and water-cooled (O/W). These systems supply air, cooled to a specified temperature by a turbo module, directly into the client’s facility. Additionally, they remove excess moisture from the air using an integrated Snow Catcher unit. This type of system is particularly well-suited for long-term storage applications where minimal maintenance or intervention is required.

Applications

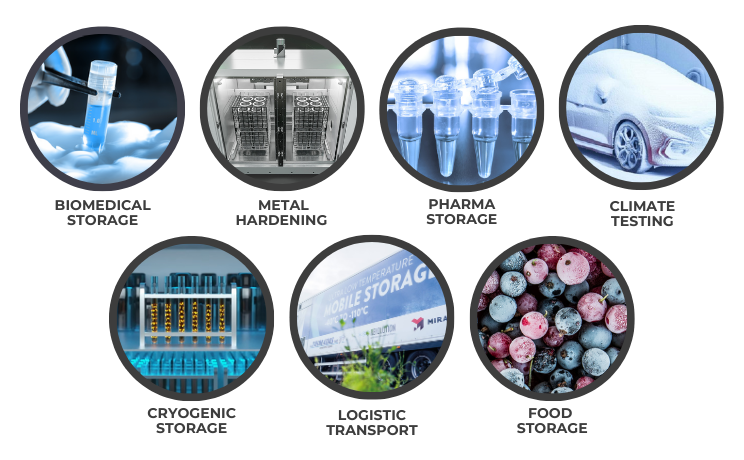

OPEN CYCLLE MACHINES APPLICATIONS

Biomedical Storage

Preservation of precious and delicate items or testing their duration through the most extreme conditions is only some of the things our solution can provide. Keep samples and sensitive materials in a homogenous environment all years round without harm.

Learn more about MIRAI Cold Products at mirai-intex.com/products

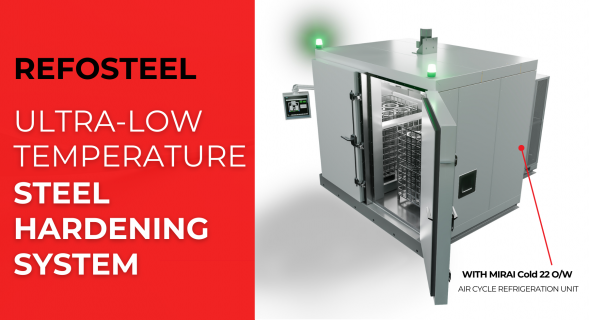

Metal Hardening

Cryogenic steel treatment is carried out at temperatures between -70°C and -120°C for one hour. It increases hardness and wear resistance by converting a higher proportion of austenite to martensite. The cooling room for cryogenic steel hardening consists of two rooms separated by a permeable barrier. Therefore, two different batches can be hardened in one machine. A heat exchange takes place between a new batch and the warm batch before the warm batch has to be cooled down to the required temperatures using an air cycle machine. This saves some of the refrigeration capacity required for cooling and reduces operating costs.

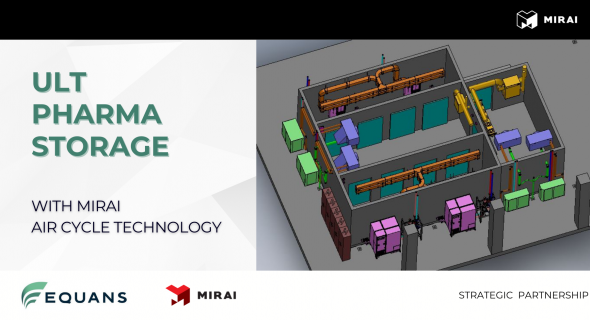

Pharma Storage

Storage, management and transportation of life-saving products such as vaccines, pharmaceuticals require a precisely coordinated chain of events under controlled temperature conditions. Temperature accuracy and quality assurance are key requirements for manufacturers. Temperature uniformity, optimum storage temperatures, electrical equipment and surface area are decisive factors in the energy efficiency of a cold store. With reliable systems, the manufacturer will never be exposed to material losses in the form of spoiled vaccines or pharmaceuticals.

Climate Testing

Testing is an important part of the product development process, control at all stages of production and pre-sale preparation of equipment, products, and devices. The main indicator of the quality of any product is resistance to temperature effects.

With highly reliable refrigeration system MIRAI COLD set and maintained temperatures have an accuracy down to the 0.5ºC via the integrated variable speed drive on the compressor.

Cryogenic Storage

Cryogenic storage of biological materials usually requires temperatures below - 130 °C. Ultra-low temperatures are achieved by cooling with clean air. Machines with temperatures down to -160 degrees Celsius are designed according to personal design and request.

Cryogenic storage needs to be foremost stable and reliable for you to be sure that stored samples are in the best conditions.

Logistic Transport

Logistic transport with ultra-low temperature capabilities is a specialized service designed to safely and efficiently transport sensitive goods that require maintenance at extremely low temperatures, typically ranging from -40°C to -150°C. This type of logistics is crucial for sectors such as healthcare, pharmaceuticals, and biotechnology, where the integrity of products like vaccines, biological samples, and certain chemicals must be preserved throughout the transportation process. Equipped with advanced cooling technologies and real-time temperature monitoring systems, these transport solutions ensure that the products remain within their required temperature range, minimizing the risk of degradation or loss of potency.

Food Storage

Storing food at -60°С stops all intra-cellular biochemical processes and denaturation of proteins, doesn’t damage tissue cells and prevents the formation of large ice crystals as it occurs at -18°C.

Cryotherapy

Cryotherapy is mainly used to relieve muscle pain, sprains and swelling after soft tissue injuries (sports) or surgery, as well as to improve recovery after sports activities.

The treatment involves exposing individuals to extremely cold dry air from − 100 °C down to – 160°C for 2-4 minutes. During these exposures, individuals wear minimal clothing to maximize the effects of cryotherapy.

Features

MIRAI INTEX has a system that’s easy to integrate and delivers consistent temperature control—without defrosting or extra equipment.

At extremely low temperatures, where moisture instantly turns to snow, the unique Snow Catcher – Humidity Extraction Device (HED) steps in to prevent frost buildup on the products. This game-changing feature eliminates the need for energy-consuming defrosting cycles, allowing the system to operate continuously and efficiently.

Installation is simple—just a few wall openings connect MIRAI Cold and the Snow Catcher, making setup as effortless as the comfort and reliability it provides.

At extremely low temperatures, where moisture instantly turns to snow, the unique Snow Catcher – Humidity Extraction Device (HED) steps in to prevent frost buildup on the products. This game-changing feature eliminates the need for energy-consuming defrosting cycles, allowing the system to operate continuously and efficiently.

Installation is simple—just a few wall openings connect MIRAI Cold and the Snow Catcher, making setup as effortless as the comfort and reliability it provides.

The principle of open cycle systems

Air is heated during compression and cooled through a series of heat exchanger sand then expanded to reach required temperatures.

While repeating the cycle of compression, cooling and expansion we can achieve temperatures down to -160°C. Operating temperature range of open-cycle machines: -40 °C to -130 °C.

Minimal service requirements

Maintenance costs are kept to a minimum. No refrigerant leakage tests, no refrigerant purchase costs and no refrigerant replenishment. Air is supplied free of charge. Long-life, wear-resistant parts and components ensure a long service life thanks to oil-free operation.

Remote monitoring

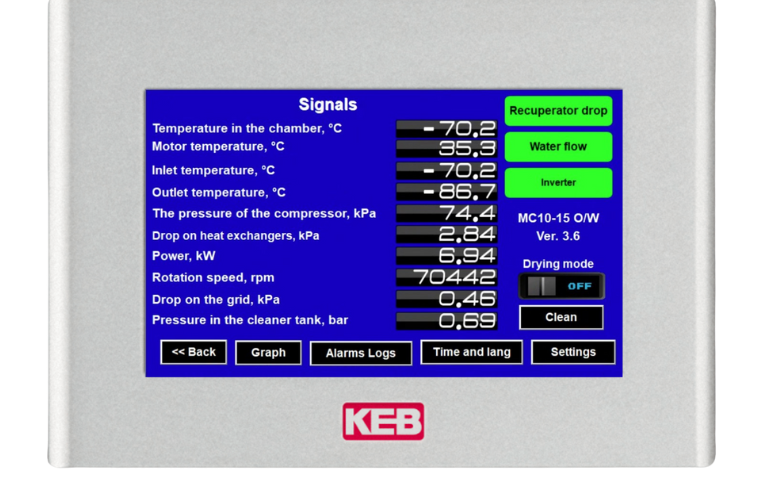

An integrated control system with easy-to-use touchscreen interface and integration of digital communication protocols such as ProfiNET, EtherCAT, EtherNET/IP and Powerlink come as standard.

The system offers real-time monitoring, data archiving and remote monitoring as options. Remote monitoring allows you to check and log machine performance, as well as update machine software online.

The system offers real-time monitoring, data archiving and remote monitoring as options. Remote monitoring allows you to check and log machine performance, as well as update machine software online.

Support from Mirai Intex during machine’s operation and during troubleshooting

Detection and prevention of problems

Regular check-ups of machine condition and performance

Case Study

August 5, 2024

Powering the Future of Sustainable Sample Storage

January 24, 2024

REFOSTEEL - Ultra-low temperature steel hardening system

January 15, 2024

Ultra-low Temperature Storage for Frigotehnica Bulgaria 2023

January 11, 2023

The latest project with MIRAI Cold machine - the Thomaidis ULT Truck

November 25, 2021

Low and Ultra-low temperature vaccine storage

November 16, 2021

MIRAI at MEDICA 2021

October 11, 2019

Cryotherapy done right