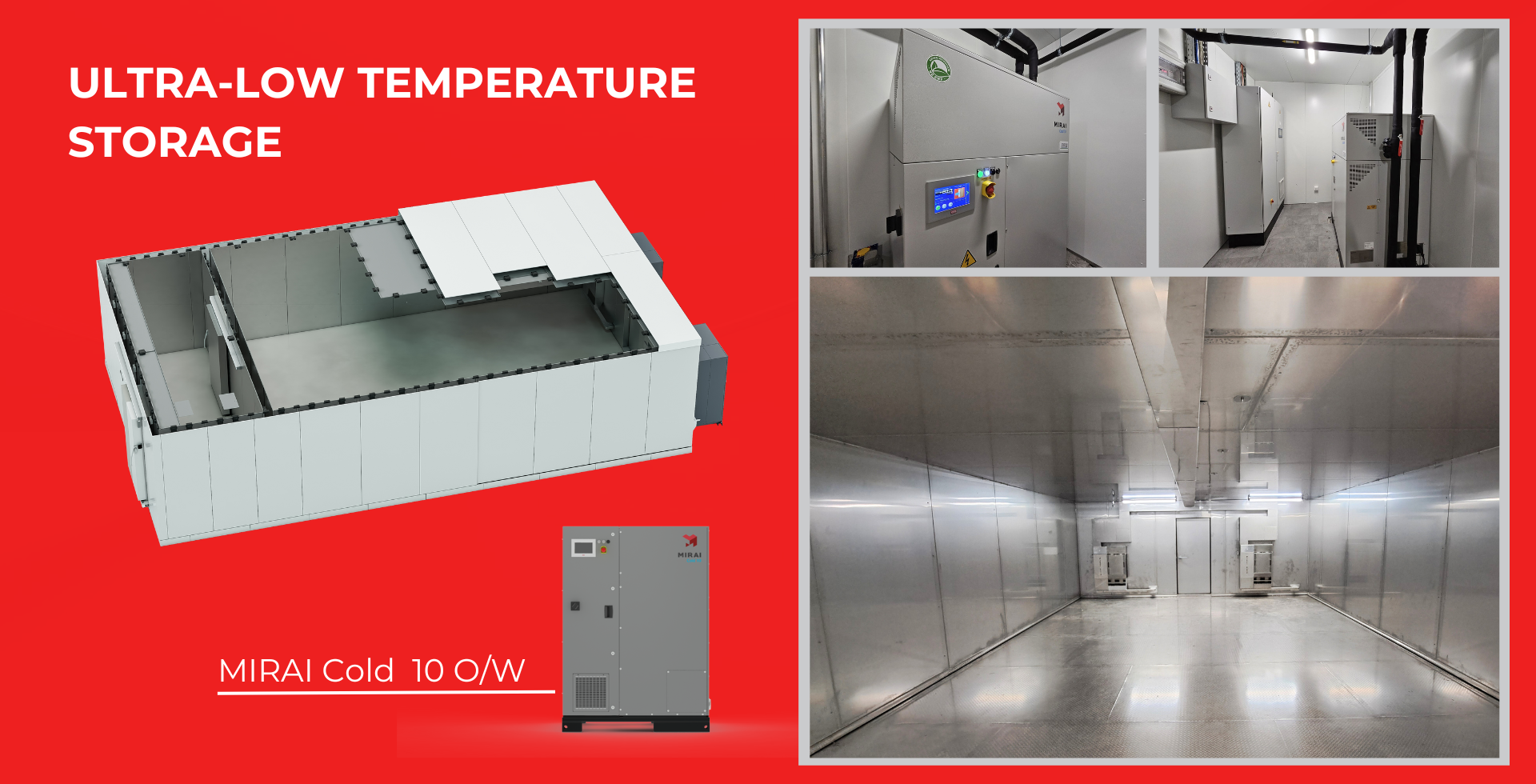

Ultra-low Temperature Storage for Frigotehnica Bulgaria 2023

PHARMACEUTICAL STORAGE - FRIGOTEHNICA BULGARIA 2023

Together with our partners Teledoor Melle Isoliertechnik GmbH and Frigotehnica Bulgaria, a low-temperature warehouse was completed in October 2023. Project management and planning for the pharmaceutical storage room were provided by our partner Refolution. MIRAI Intex® supplied two MIRAI Cold ULT refrigeration unites. Through collaboration with all project partners, the realization of this storage room became possible.

The storage room has a storage area of 51 m² and a storage volume of 119 m³. Thanks to the MIRAI Intex® technology the storage room can be continuously controlled to temperatures between -80°C and -20°C. The two MIRAI Cold 10 O/W machines with air as the refrigerant ensure N+1 redundancy. The control quality is +/- 0.5 K with a temperature homogeneity of 2 K in an empty room. This requirement is always met thanks to mechanical defrosting. At the same time, the air is dried by reducing the dew point by approx. 15 K. This ensures particularly high product quality during storage. The speed control enables particularly efficient partial load operation of the systems at any temperature requirement. The cooling water system is implemented via two redundant R290 chillers (propane chillers) from Secon, type HELIOS. This means that all system-relevant components are redundant. In addition, the entire installation is protected against power failure by an emergency diesel generator, thus always ensuring safe storage. For energy optimization and ice fog reduction, a corresponding airlock system with a self-sufficient CO2 (R744) cooling unit was integrated, which always ensures temperature control. The airlock reduces the input of humidity into the chamber.

TECHNOLOGY

A safety concept was implemented that includes personal safety when entering the ultra-low temperature storage room by means of a dead man's alarm and cryogenic clothing (PPE) as well as safety against CO2 leakage. This storage room was designed to meet the customer's needs and given space with a storage system, safety, loading and unloading concepts. It consists of special stainless steel industrial panels with PU foam filling, which are mechanically stable enough for extreme temperatures and achieve an outstanding insulating effect. The machine control system was implemented with a Siemens S7 and the developed safety concepts and equipped with remote maintenance access and various customer interfaces. The equipment in the storage rooms includes temperature monitoring, economical LED lighting with high luminous efficiency and low heat input, stainless steel interior walls and a heavy-duty floor (20 kN/m²). Thanks to the exclusive use of natural refrigerants, the system is an environmentally friendly, efficient, and safe low-temperature storage facility. In addition to the choice of system technology, a long service life is also guaranteed by the selection of refrigerants that are free from legal restrictions (F-Gas Regulation and PFAS Regulation).