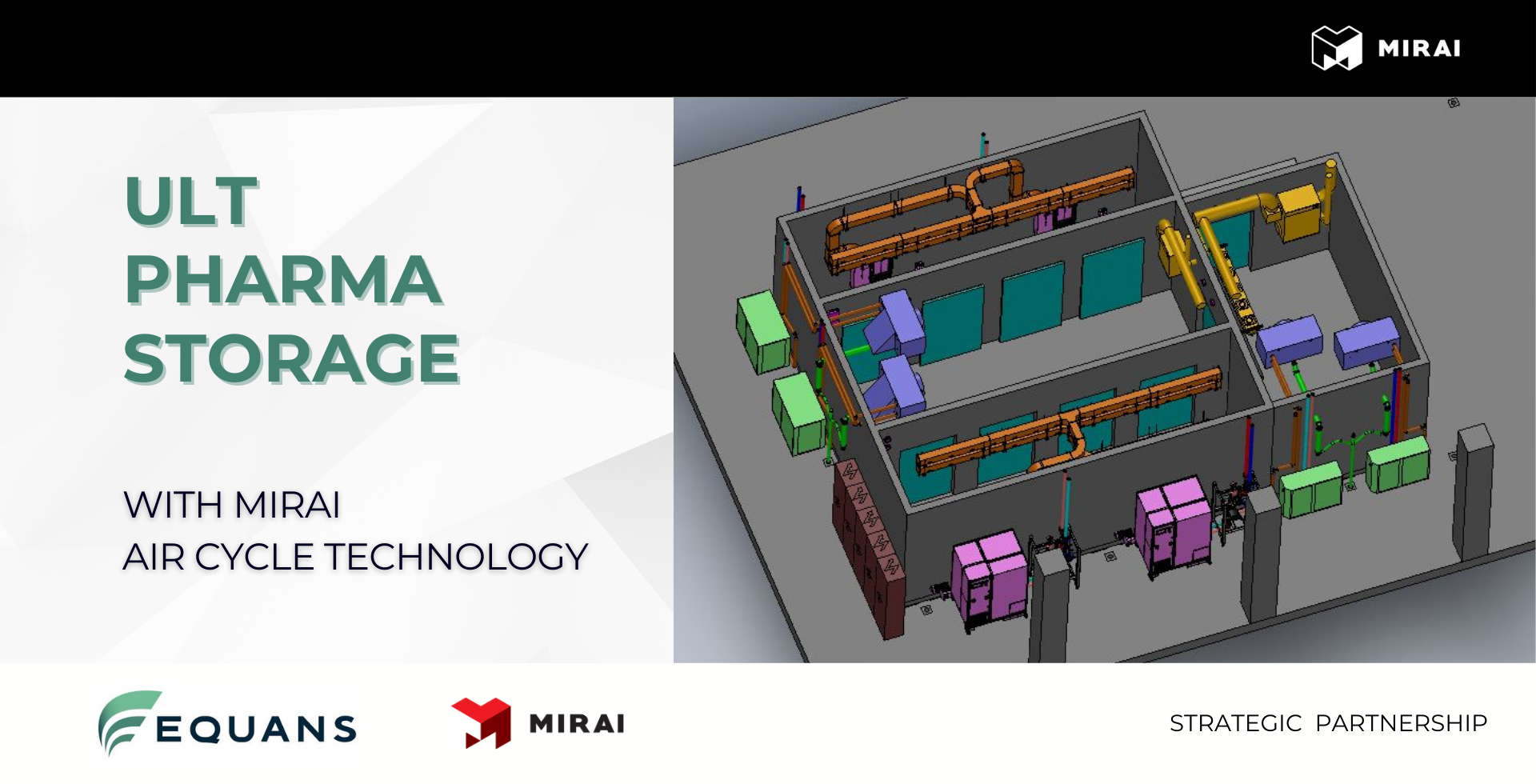

MIRAI Intex Delivers Cutting-Edge Refrigeration Solution to Leading Pharmaceutical Site Near Strasbourg

In a significant stride towards eco-friendly and sustainable refrigeration, MIRAI Intex has proudly announced its latest accomplishment in supplying advanced refrigeration technology to a key pharmaceutical project led by Axima Refrigeration France. This ambitious initiative, situated near Strasbourg, marks a milestone in the refrigeration industry, particularly for applications requiring ultra-low temperatures.

A Glance at the Project

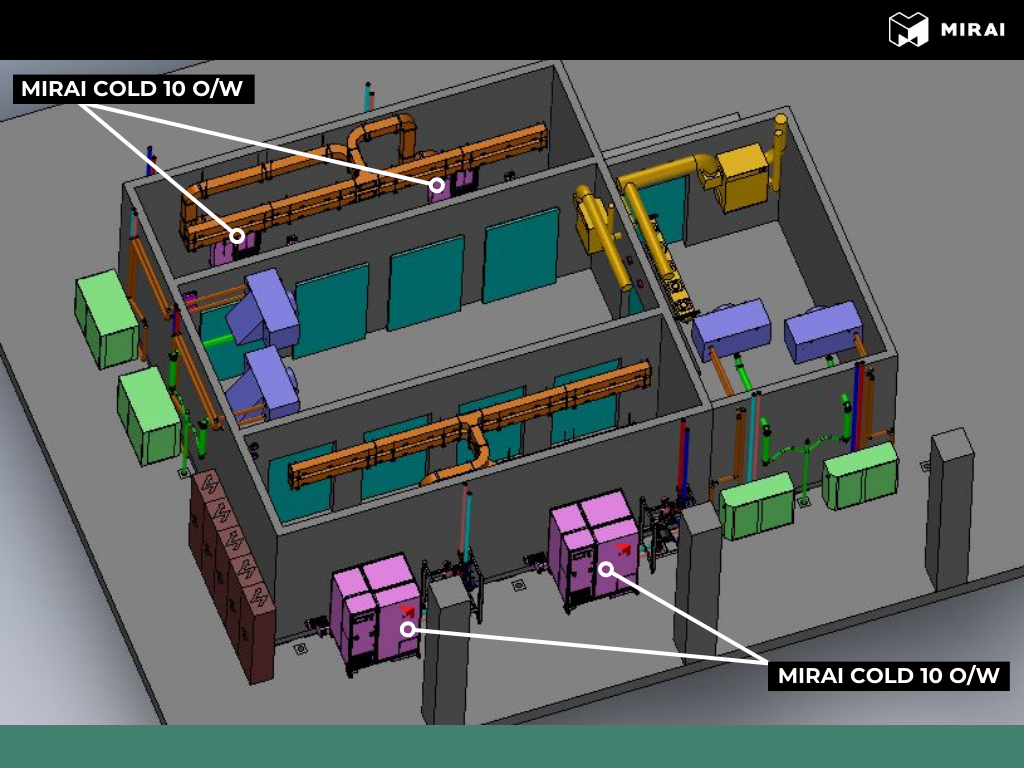

The project's central focus was to meet the demanding temperature requirements of two primary storage chambers, each necessitating a consistent temperature of -70°C. To achieve this, we have installed four MIRAI Cold air cycle refrigeration systems, model MC 10 O/W, in an open cycle configuration. Additionally, a pre-chamber linking these storage areas is maintained at -20°C, utilizing a dedicated CO2 refrigeration unit for cooling. This integrated solution ensures precise temperature control while maximizing energy efficiency.

Innovation and Sustainability at Its Core

MIRAI Intex's air cycle technology stands out for its environmental credentials, boasting a Global Warming Potential (GWP) of 1. This figure is particularly noteworthy, highlighting the system's minimal environmental impact in comparison to traditional refrigeration methods. The entire installation exemplifies a leap forward in achieving sustainable cooling solutions without compromising on performance.

Enhanced Temperature Uniformity and Safety

One of the defining features of the MIRAI Cold refrigeration systems is their ability to deliver exceptional temperature uniformity and precision. This is accomplished through a carefully engineered air distribution system that channels air directly into the cold rooms via specially designed ducts. Such meticulous air management ensures that even at extreme temperatures, the stored pharmaceuticals are kept in optimal conditions.

Safety has also been a paramount consideration in the design and installation of this system. With numerous safety mechanisms in place, the facility is equipped to operate continuously and reliably, ensuring that critical pharmaceutical products are maintained in their ideal states without the risk of temperature deviations or system failures.

Redundancy for Reliability

Understanding the critical nature of pharmaceutical storage, MIRAI Intex has incorporated an N+1 redundancy setup within the refrigeration system. This design principle ensures that an additional refrigeration unit is always available to take over in the event of any single unit's failure, thus guaranteeing uninterrupted operation and peace of mind for the pharmaceutical company.

A Partnership for the Future

The collaboration between MIRAI Intex and Axima Refrigeration France in bringing this project to fruition underscores the potential for innovative technologies to revolutionize the refrigeration industry. This venture not only demonstrates the practical applications of air cycle refrigeration in demanding environments but also sets a new benchmark for sustainability and efficiency in cooling technologies.

As the world increasingly leans towards green and sustainable solutions, projects like the one near Strasbourg serve as beacons of innovation, showing how technology and environmental stewardship can go hand in hand. MIRAI Intex remains at the forefront of this movement, committed to delivering refrigeration solutions that meet the dual demands of performance and environmental responsibility.

For more information, please contact sales@mirai-intex.com