Features

MIRAI Cold 10 C/W/T is the most compact closed-cycle cooling machine in the MIRAI range, water-cooled and designed as the ideal solution for small-scale process cooling applications or freeze dryers. The system operates in a closed indirect refrigeration cycle, using Air as the refrigerant — a sustainable, eco-friendly, and fluorocarbon-free choice.

Operating temperature range:

Standard: from –40 °C to –120 °C

Optional: down to –160 °C, available on request and depending on the properties of your HTF.

The machine is equipped with a factory-installed heat exchanger, compatible with different heat transfer fluids (HTF). The unit does not include any pumps or heating elements (heaters). You must supply your HTF to the integrated heat exchanger using your external pump.

Engineering support is required for proper system integration. The Mirai Intex engineering team will assist you with seamless integration of the unit into your setup — this applies to all C/W/T models. Optionally, the system can be delivered with remote monitoring and control capabilities, upon request.

Next advantage of every MIRAI Intex cooling machine is rapid automatic restart of the cooling machine in case of power interruptions.

In the event of power outages or voltage fluctuations on the customer’s side, MIRAI systems can automatically restart and restore all operating parameters within 30 seconds — without requiring operator intervention.

Operating temperature range:

Standard: from –40 °C to –120 °C

Optional: down to –160 °C, available on request and depending on the properties of your HTF.

The machine is equipped with a factory-installed heat exchanger, compatible with different heat transfer fluids (HTF). The unit does not include any pumps or heating elements (heaters). You must supply your HTF to the integrated heat exchanger using your external pump.

Engineering support is required for proper system integration. The Mirai Intex engineering team will assist you with seamless integration of the unit into your setup — this applies to all C/W/T models. Optionally, the system can be delivered with remote monitoring and control capabilities, upon request.

Next advantage of every MIRAI Intex cooling machine is rapid automatic restart of the cooling machine in case of power interruptions.

In the event of power outages or voltage fluctuations on the customer’s side, MIRAI systems can automatically restart and restore all operating parameters within 30 seconds — without requiring operator intervention.

Reduced power consumption up to

30%

Eco-Friendly

- Air as Refrigerant

- No need to refilling

- Environmentally friendly

Temperature accuracy of

0.5°C

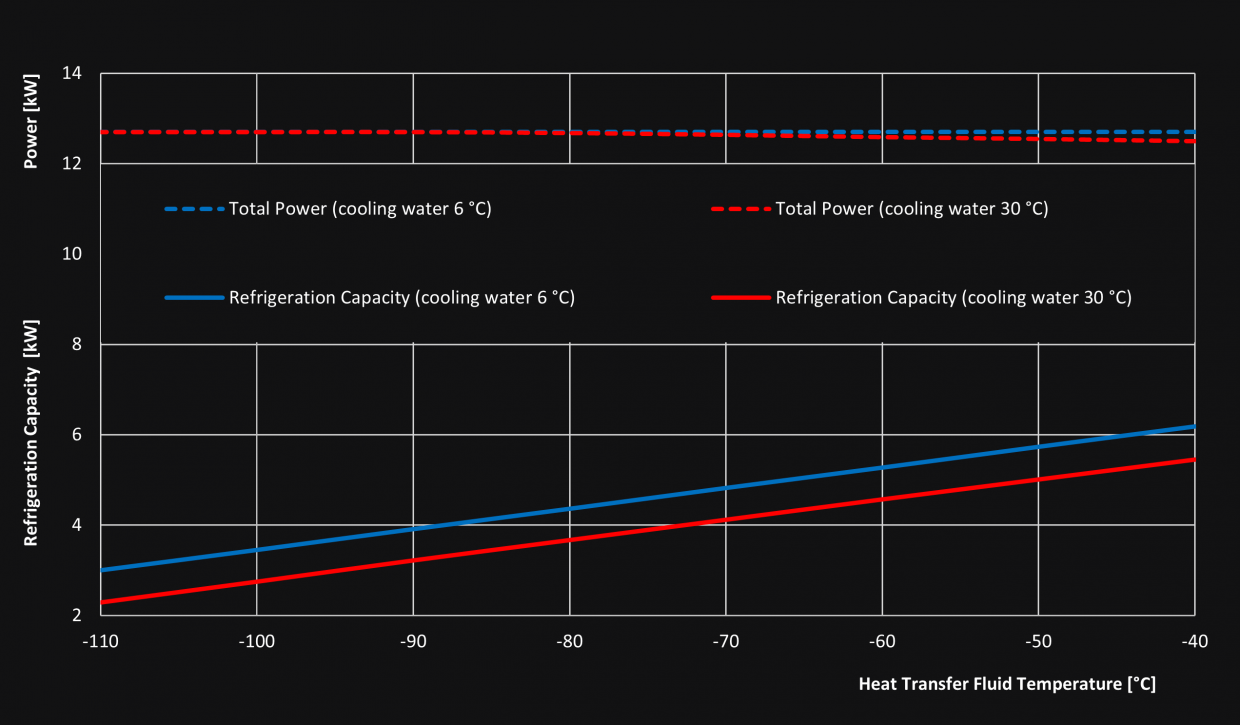

Cooling capacity & Power

MIRAI Cold 10 T (MC 10 C/W/T)

Additional Heat Exchanger

Closed cycle machines are factory equipped with an additional heat exchanger. The ultra-low temperature air is working in a closed loop by cooling down a heat transfer fluid in this additional heat exchanger.

Electrical Cabinet Air Filter Cartridge

The only part requiring regular attention. Each 9000 operating hours or by machine’s demand cartridge needs to be replaced. Simple task not requiring any special training or certification.

Control Panel

User-friendly interface and easy control of the machine is provided by 7” color touch screen panel. System is compatible with digital communication protocols ProfiNET, EtherCAT, EtherNET/IP, and Powerlink.

Technical Data

Refrigerant

Natural Air

Dimensions (WxDxH)

133x99x179 cm

Rated Motor Power

10 kW

Weight

790 kg

Noise Level

up to 70 dB

Operation Cycle

Closed cycle

System Cooling Water

Water-cooled

Temperature Range

from -40°C to -160°C

Max Rotation Speed

82 000 rpm

Similar Products

MIRAI INTEX works only with the safest & most natural refrigerants.

MIRAI Cold 10 T

Do you need more information about MIRAI COLD 10 T? Don´t hesitate and get in touch with us.