MIRAI X CRYO

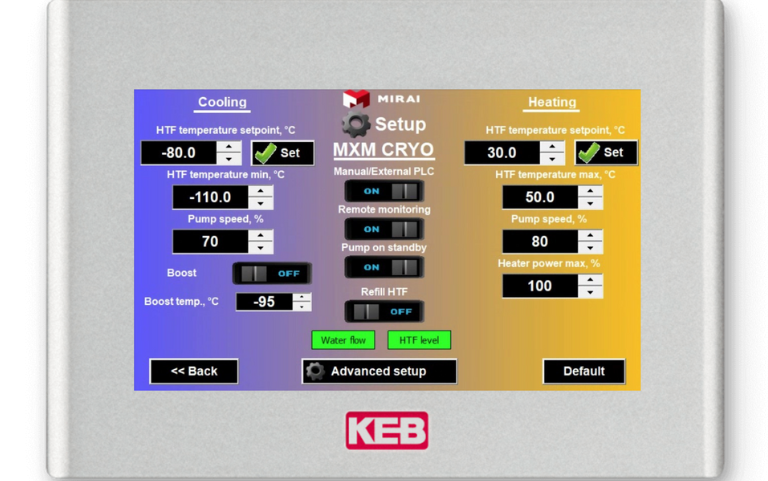

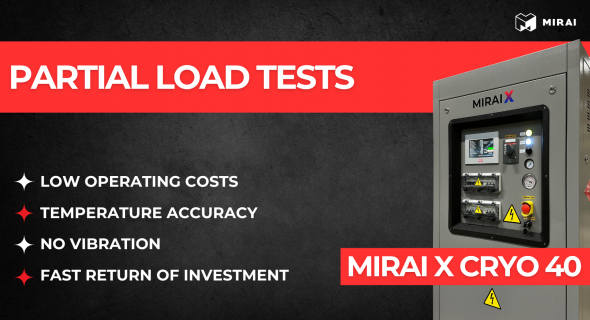

The MIRAI X CRYO line includes compact, closed-cycle machines with different power capacity, designed for a wide temperature range, Plug & Play integration, and easy operation. Ideal for diverse industries like pharma, semiconductors, coating, and ultra-low temp storage under intensive use. MIRAI X CRYO – Versatile base model for reliable cooling and heating with automated control and high temperature stability. MIRAI XM CRYO – A compact next-gen model with ~26% smaller footprint, offering the same performance for space-constrained environments. MIRAI XS CRYO – Tailored for ultra-fast switching between heating and cooling, with dual independent loops — perfect for semicon and coating applications.

Applications

MIRAI X CRYO MACHINES APPLICATIONS

Semiconductor Testing

In semiconductor testing, cold temperatures are critical for evaluating device performance under extreme conditions. Lower temperatures can reveal hidden defects by affecting electron mobility and material properties, ensuring that semiconductors operate reliably in a wide range of environments. This testing phase is essential for identifying potential failures before mass production, guaranteeing the durability and reliability of electronic components in various applications.

Biomedical Storage

Preservation of precious and delicate items or testing their duration through the most extreme conditions is only some of the things our solution can provide. Keep samples and sensitive materials in a homogenous environment all years round without harm.

Learn more about MIRAI Cold Products at mirai-intex.com/products

Metal Hardening

Cryogenic steel treatment is carried out at temperatures between -70°C and -120°C for one hour. It increases hardness and wear resistance by converting a higher proportion of austenite to martensite. The cooling room for cryogenic steel hardening consists of two rooms separated by a permeable barrier. Therefore, two different batches can be hardened in one machine. A heat exchange takes place between a new batch and the warm batch before the warm batch has to be cooled down to the required temperatures using an air cycle machine. This saves some of the refrigeration capacity required for cooling and reduces operating costs.

Dry Etching

Dry etching is a precise technique used in microelectronics, relying on reactive gases to shape semiconductor surfaces. Cold in the temperature range from -70°C to -120°C plays a vital role, improving etching accuracy by slowing unwanted reactions, thus ensuring only targeted areas are etched. This precision is crucial for creating complex, reliable electronic devices.

Semiconductor Manufacturing

MIRAI Intex has developed a new product line, MIRAI X CRYO, designed with a temperature range from -120°C to +50°C, promising unparalleled performance and temperature accuracy for various industrial applications, especially for semiconductor manufacturing and the dry etch processes.

Pharma Storage

Storage, management and transportation of life-saving products such as vaccines, pharmaceuticals require a precisely coordinated chain of events under controlled temperature conditions. Temperature accuracy and quality assurance are key requirements for manufacturers. Temperature uniformity, optimum storage temperatures, electrical equipment and surface area are decisive factors in the energy efficiency of a cold store. With reliable systems, the manufacturer will never be exposed to material losses in the form of spoiled vaccines or pharmaceuticals.

Lyophilization

Lyophilization, also known as freeze-drying, is a sophisticated dehydration process widely used in pharmaceuticals, biotechnology, and food preservation to extend the shelf life of products while maintaining their structural integrity and bioactivity. This method is particularly valuable for preserving sensitive materials like vaccines, antibiotics, and specialty foods.

Climate Testing

Testing is an important part of the product development process, control at all stages of production and pre-sale preparation of equipment, products, and devices. The main indicator of the quality of any product is resistance to temperature effects.

With highly reliable refrigeration system MIRAI COLD set and maintained temperatures have an accuracy down to the 0.5ºC via the integrated variable speed drive on the compressor.

Chemical Processes

Chemical processes often involve reactions that can be exquisitely sensitive to temperature changes. Cold temperatures play a crucial role in many of these processes by slowing down reaction rates, thus offering greater control over the reaction's outcome. This is particularly important in reactions that are highly exothermic, where excessive heat can lead to runaway reactions or in processes where selectivity and product purity are paramount. By carefully managing temperatures, chemists can steer reactions to favor the formation of desired products while minimizing side reactions and degradation of sensitive compounds. This level of control is indispensable in the synthesis of complex pharmaceuticals, fine chemicals, and in various analytical procedures where precision and reliability are essential.

Cryogenic Storage

Cryogenic storage of biological materials usually requires temperatures below - 130 °C. Ultra-low temperatures are achieved by cooling with clean air. Machines with temperatures down to -160 degrees Celsius are designed according to personal design and request.

Cryogenic storage needs to be foremost stable and reliable for you to be sure that stored samples are in the best conditions.

Logistic Transport

Logistic transport with ultra-low temperature capabilities is a specialized service designed to safely and efficiently transport sensitive goods that require maintenance at extremely low temperatures, typically ranging from -40°C to -150°C. This type of logistics is crucial for sectors such as healthcare, pharmaceuticals, and biotechnology, where the integrity of products like vaccines, biological samples, and certain chemicals must be preserved throughout the transportation process. Equipped with advanced cooling technologies and real-time temperature monitoring systems, these transport solutions ensure that the products remain within their required temperature range, minimizing the risk of degradation or loss of potency.

Physical Vapor Deposition

Temperatures in the application of physical vapor deposition from -140℃ to +50℃ increase the speed of vacuum processes, for which the MIRAI X CRYO machine is ideal and can be easily connected to a PVD system.

Freeze Drying

Freeze drying is a freeze drying process in which water is removed from the product after it has been frozen and placed under vacuum, thus allowing the ice crystals to pass directly from the solid state to the vapour state. The process is based on the physical phenomenon of sublimation, which allows a direct transition from the solid to the liquid state. Lyophilisation is mainly used in pharmaceutical and biotechnological research and the industrial production of cosmetic products or drugs such as tablets but also in the drying of foodstuffs and the preservation of archival materials (i.e. books and documents).

Space Equipment Testing

In space equipment testing, cold temperatures are crucial for simulating the harsh conditions of space, where equipment must perform reliably. This testing ensures that materials and components can withstand extreme cold without failing, essential for the success of space missions and the safety of astronauts.

Solvent Recovery

Solvent Recovery is based on the fact that the vapor of a boiling mixture will be richer in low boiling point components such as alcohols, acetones, aliphatic hydrocarbons and, ketones. When the vapor is cooled and condensed, the liquid condensate becomes a valuable product that can be sold back into the industrial marketplace.

A solvent recovery system is the preferred recycling method among many industrial manufacturers since it provides a cost-effective solvent recuperation solution and minimizes adverse environmental effects.

Only natural refrigerant (AIR) is used in multiple stages of the refrigeration process. The ultra-low temperature process is realized with a MIRAI INTEX air cycle refrigeration solution MIRAI Cold.

Food Storage

Storing food at -60°С stops all intra-cellular biochemical processes and denaturation of proteins, doesn’t damage tissue cells and prevents the formation of large ice crystals as it occurs at -18°C.

Freezing Chambers

Freeze chambers, commonly known in scientific and industrial contexts, are crucial for preserving biological samples, such as cells and tissues, at extremely low temperatures. They play a vital role in materials science for testing the durability of materials under cold conditions and in the food industry for flash-freezing to retain freshness.

Process Cooling

Large industrial plants or facilities need to cool their production processes almost all year round. Mirai solution is not only environmentally friendly and free of any F-gases or oils, but it is also extremely efficient. The primary role of cooling systems in industrial refrigeration systems is not only to be extremely efficient, reliable and cost-effective, but also to improve the initial production processes and contribute to environmental protection.

Industrial Cooling Processes

In cooling processes, cold temperatures are essential for efficiently reducing the heat in systems or materials. This is crucial for maintaining optimal operating conditions in machinery, preventing overheating, and preserving the integrity of temperature-sensitive products. Effective cooling ensures longevity and reliability across various applications, from industrial machinery to food preservation.

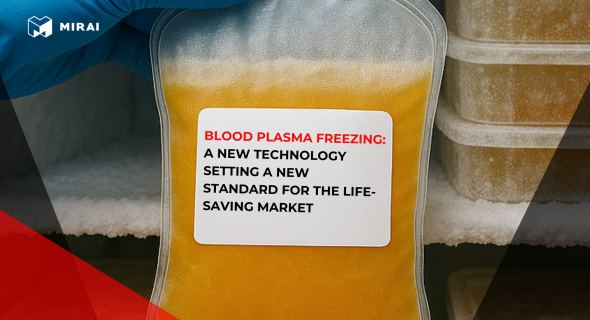

Blood Plasma Freezing

For demanding processes in the manufacture of pharmaceutical and biotechnological products in the temperature range down to -90 °C.

Cryotherapy

Cryotherapy is mainly used to relieve muscle pain, sprains and swelling after soft tissue injuries (sports) or surgery, as well as to improve recovery after sports activities.

The treatment involves exposing individuals to extremely cold dry air from − 100 °C down to – 160°C for 2-4 minutes. During these exposures, individuals wear minimal clothing to maximize the effects of cryotherapy.

PLUG & PLAY

The MIRAI X CRYO machine is the ideal solution for retrofitting in existing installation and is easy to implement in new projects due to its Plug & Play design, compatible with multiple industry standard connection types.

See the MIRAI X CRYO chiller in action across various industries, from vacuum coating and semiconductor manufacturing to food processing and pharmaceuticals.

Minimal service requirements

Maintenance costs are kept to a minimum. No refrigerant leakage tests, no refrigerant purchase costs and no refrigerant replenishment. Air is supplied free of charge. Long-life, wear-resistant parts and components ensure a long service life thanks to oil-free operation.

Remote monitoring

MIRAI INTEX provides several remote monitoring options for their customers. If you're an end customer, distributor, or service provider who wants to enhance safety and increase the longevity of your projects that utilize MIRAI X CRYO machines, this solution is the perfect choice.

Support from Mirai Intex during machine’s operation and during troubleshooting

Detection and prevention of problems

Regular check-ups of machine condition and performance

Case Study

May 14, 2025

MIRAI INTEX IS REVOLUTIONIZING CRYOGENIC TECHNOLOGY

March 18, 2025

Cooling Reinvented – MIRAI X CRYO by Mirai Intex

October 29, 2024

MIRAI INTEX EXTENDS THE MX SEMI LINEUP

September 23, 2024

MIRAI INTEX WINS REFRIGERATION INNOVATION OF THE YEAR