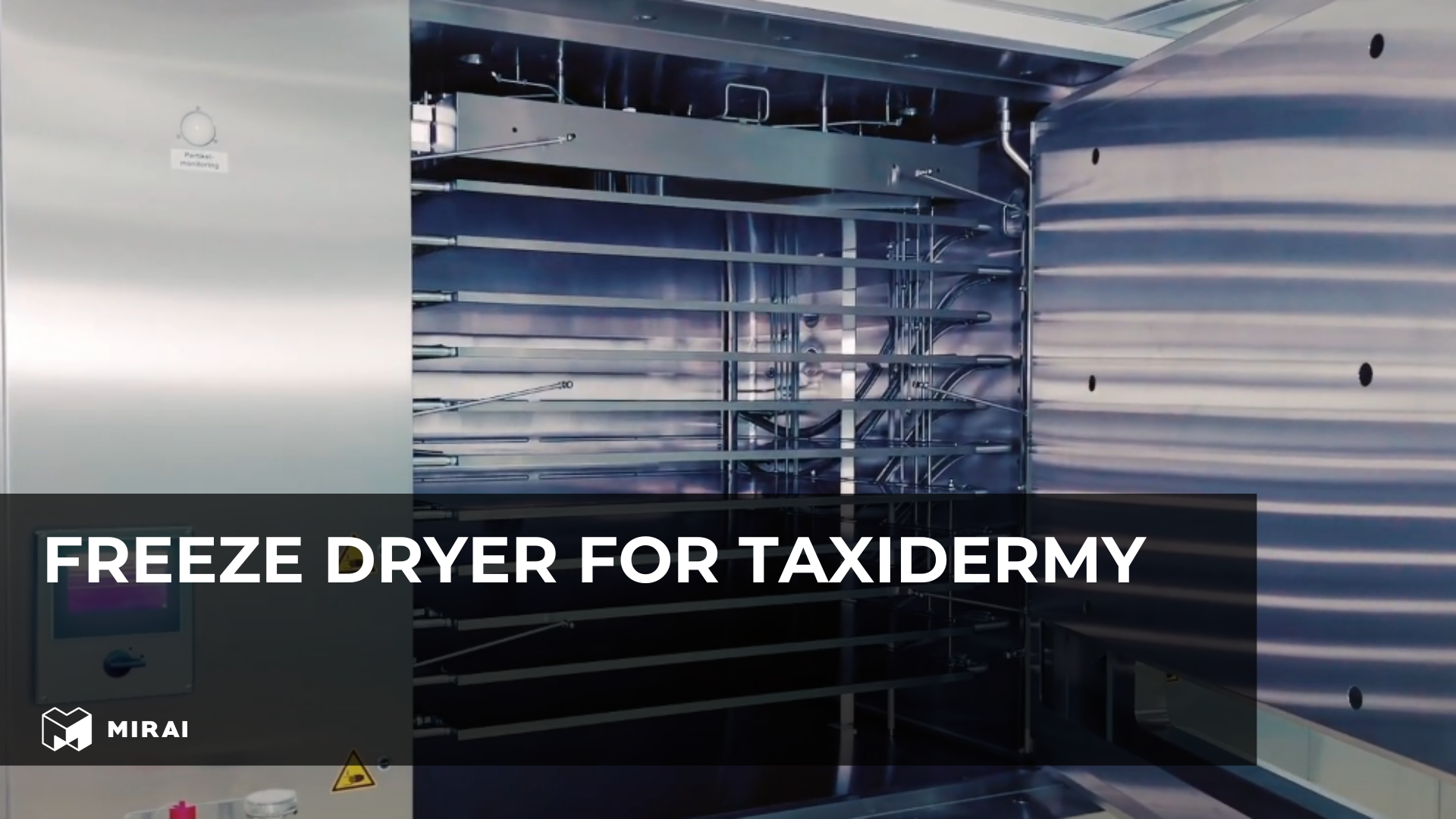

Freeze dryer for taxidermy

Taxidermy, the art of preserving animal bodies for display or study, has been practiced for centuries. Traditionally, taxidermists have relied on various methods to preserve specimens, but recent advancements in technology have introduced freeze drying as a superior alternative. This article explores the role of taxidermy freeze dryers, the principles of sublimation drying, and the advantages of using freeze drying technology in taxidermy.

Traditional methods

Conventional Preservation Techniques

Traditional taxidermy involves methods such as:

- Chemical Preservation: Using substances like borax or formaldehyde to treat the animal skin.

- Dehydration: Removing moisture from the specimen through air drying or desiccants.

- Tanning: Treating the animal hide with chemicals to prevent decomposition and maintain flexibility.

While these methods can be effective, they often involve significant manual labor, exposure to potentially harmful chemicals, and can result in shrinkage or distortion of the specimen.

Challenges with traditional methods

In addition to the challenges already mentioned, traditional taxidermy methods face several other significant obstacles:

- Environmental impact: Many traditional preservatives and chemicals used in taxidermy are not environmentally friendly. Disposal of these substances can lead to pollution and long-term environmental damage.

- Limited durability: Specimens prepared using conventional techniques may not withstand the test of time. Over the years, exposure to varying temperatures and humidity can degrade the quality of the taxidermy, causing it to deteriorate more quickly.

- Skill dependency: Traditional taxidermy is highly dependent on the skill level and experience of the taxidermist. Even minor errors during the preparation process can result in unsatisfactory results, affecting the overall quality of the specimen.

- Health hazards: Prolonged exposure to certain chemicals used in traditional taxidermy, such as formaldehyde and arsenic, can pose significant health risks. These substances are toxic and can lead to serious health conditions if proper safety measures are not taken.

- Cost: The materials and tools required for traditional taxidermy can be expensive. Coupled with the labor-intensive nature of the work, this can make traditional taxidermy a costly endeavor.

- Accessibility: Learning traditional taxidermy requires significant time and dedication. Access to quality training and apprenticeships can be limited, creating barriers for those interested in entering the field.

- Ethical concerns: Traditional taxidermy practices often raise ethical questions, particularly concerning the sourcing of specimens. Ensuring that animals are obtained ethically and legally is crucial, but not always straightforward.

Addressing these challenges requires a combination of innovation and adherence to best practices. Modern techniques and materials are increasingly being adopted to mitigate these issues, providing safer, more efficient, and environmentally friendly alternatives to traditional taxidermy methods. By embracing these advancements, taxidermists can achieve higher quality results while minimizing the negative impacts associated with traditional practices.

Sublimation drying

Advantages of lyophilization in taxidermy

-

Enhanced preservation: Lyophilization offers superior preservation of the specimen's structure, color, and texture compared to traditional methods. By preventing the collapse of cellular structures, it maintains a lifelike appearance.

-

Reduced shrinkage and cracking: The controlled environment of the freeze-drying process minimizes the risk of shrinkage and cracking, common issues with traditional drying methods.

-

Longevity: Specimens preserved through lyophilization tend to have a longer lifespan. They are less susceptible to deterioration caused by environmental factors such as humidity and temperature fluctuations.

-

Minimized chemical exposure: Unlike traditional methods that often require hazardous chemicals, lyophilization significantly reduces the need for toxic preservatives, making it a safer option for taxidermists.

-

Detail Preservation: The meticulous process of lyophilization preserves fine details of the specimen, from delicate feathers to intricate skin patterns, providing a more realistic and detailed final product.

Applications Beyond Taxidermy

- Pharmaceuticals: Lyophilization is widely used in the pharmaceutical industry to stabilize vaccines, biological samples, and other heat-sensitive drugs. It extends the shelf life and ensures the efficacy of these products.

- Food industry: Freeze drying is also popular in the food industry for preserving fruits, vegetables, and ready-to-eat meals. It retains nutritional value, flavor, and texture while significantly reducing weight and volume for easier storage and transport.

- Biological research: In biological research, lyophilization is employed to preserve specimens for long-term storage and study. It maintains the integrity of biological samples, enabling reliable research outcomes.

Challenges and Considerations

- Cost: The initial investment in lyophilization equipment can be high. Additionally, operating costs, including energy consumption and maintenance, need to be considered.

- Technical expertise: Successful lyophilization requires a thorough understanding of the process and precise control over the conditions within the drying chamber. Taxidermists may need specialized training to achieve optimal results.

- Time-consuming: The lyophilization process can be time-consuming. Each stage, particularly primary drying, must be carefully monitored and can take several hours to days, depending on the specimen's size and complexity.

- Equipment maintenance: Regular maintenance of lyophilization equipment is crucial to ensure its efficient operation. Any malfunction can disrupt the delicate balance required for successful freeze drying.

Future prospects

With continuous advancements in technology, lyophilization is becoming more accessible and efficient. Innovations such as automated control systems and energy-efficient designs are making the process more practical for widespread use in taxidermy and other fields.

Incorporating lyophilization into taxidermy practices not only enhances the quality and longevity of preserved specimens but also opens new possibilities for scientific research and commercial applications. As the technique becomes more refined, it is poised to become a standard practice for high-quality preservation across various industries.

Advantages and working principles of the technology

Advantages of freeze drying in taxidermy

- Precision Preservation: Maintains the original shape, size, and appearance of the specimen without shrinkage.

- Chemical-Free: Eliminates the need for harmful chemicals, ensuring a safer working environment.

- Durability: Results in long-lasting mounts that are less susceptible to environmental changes.

Working principles of a taxidermy freeze dryer

A freeze dryer for taxidermy operates by creating a controlled environment where sublimation can occur efficiently. The process involves:

- Vacuum Chamber: A sealed environment where pressure is reduced to facilitate sublimation.

- Temperature Control: Precise control over temperature to ensure gradual and thorough drying.

- Moisture Removal: Systems to capture and remove water vapor from the chamber, preventing rehydration of the specimen.

Equipment Used

Key Components of freeze dry taxidermy equipment

- Freeze dry machine for taxidermy: The main apparatus that houses the specimen and controls the drying process.

- Vacuum pump: Creates the low-pressure environment necessary for sublimation.

- Heating elements: Gradually raise the temperature to facilitate sublimation without damaging the specimen.

- Condenser: Captures and removes water vapor from the chamber.

Additional supplies and equipment

- Specimen mounts: Structures to support the specimen during the drying process.

- Moisture sensors: Devices to monitor the moisture levels within the chamber.

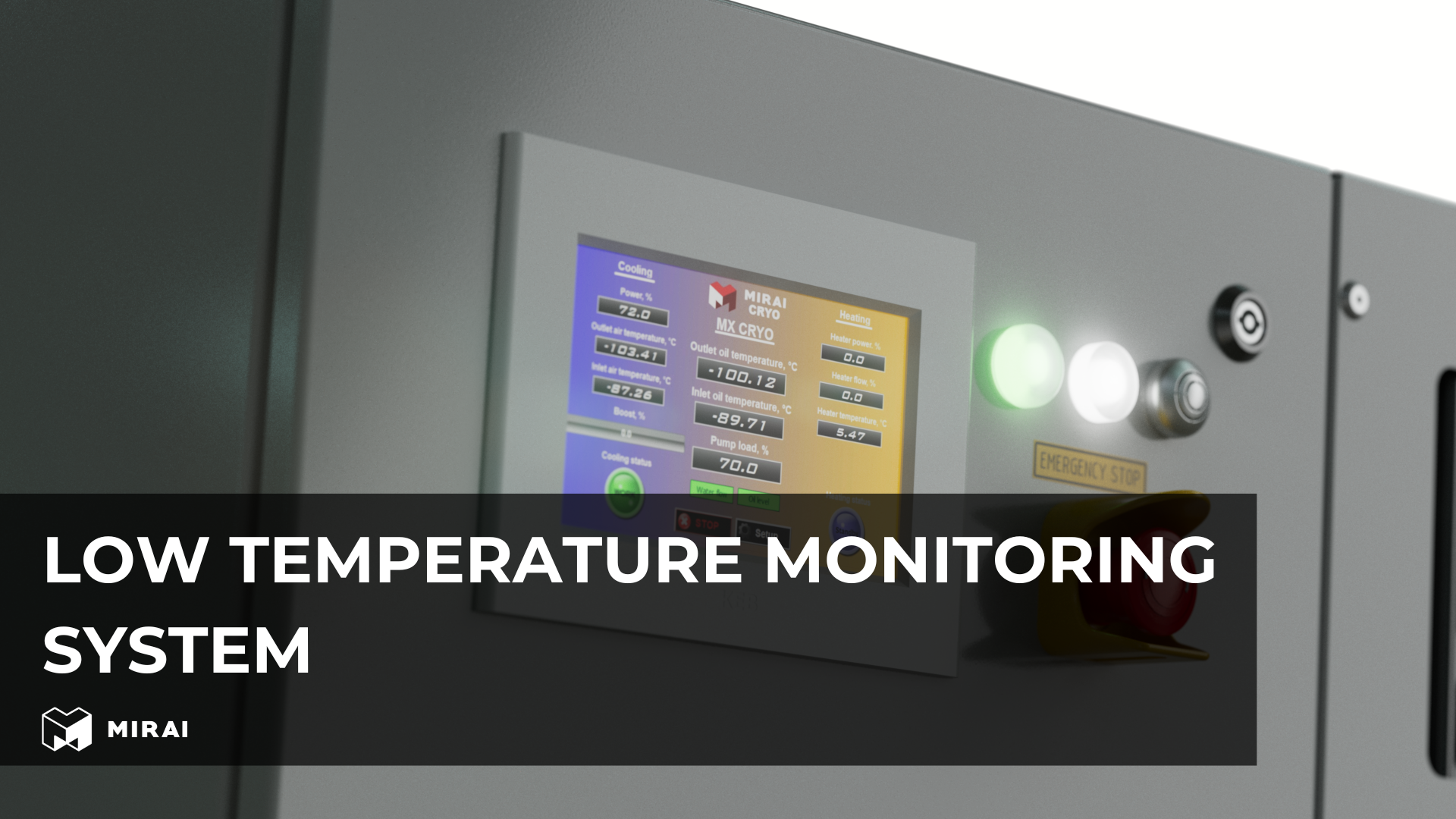

- Control systems: Automated systems to manage the temperature, pressure, and drying time.

Which Mirai machines can be used in this process

Mirai has extensive experience in the pharmaceutical freeze drying industry with market leaders such as: GEA, IMA Life, CSL Behring, realized numerous projects with HOF and Refolution in this industry.

Mirai technologies used in freeze drying

Mirai's closed cycle machines are suitable for freeze drying.

They differ in the cooling capacity required for the installation and its size.

Mirai machines are designed to increase the efficiency and effectiveness of freeze drying. These include:

- Precision Temperature Control Systems: Provide precise temperature control throughout the drying process.

- Automated control systems: Allow precise control and adjustment, reducing manual intervention and ensuring consistent results.

Benefits of using Mirai technologies

- Improved preservation: Preserves the integrity and appearance of samples.

- Efficiency: Reduces drying time and increases throughput.

- Reliability: Consistent results with minimal risk of sample damage.

- Environmentally friendly and safe: Mirai uses only air for cooling in its machines, ensuring safety and no need for extraneous chemistry in the process.

Conclusion

The adoption of freeze drying technology in taxidermy represents a significant advancement over traditional preservation methods. By utilizing a taxidermy freeze dryer, taxidermists can achieve superior preservation with less labor and without harmful chemicals. The integration of advanced technologies, such as those offered by Mirai, further enhances the process, ensuring precision, efficiency, and reliability. As the field of taxidermy continues to evolve, the use of freeze drying and related technologies will undoubtedly play a pivotal role in advancing the art and science of specimen preservation.