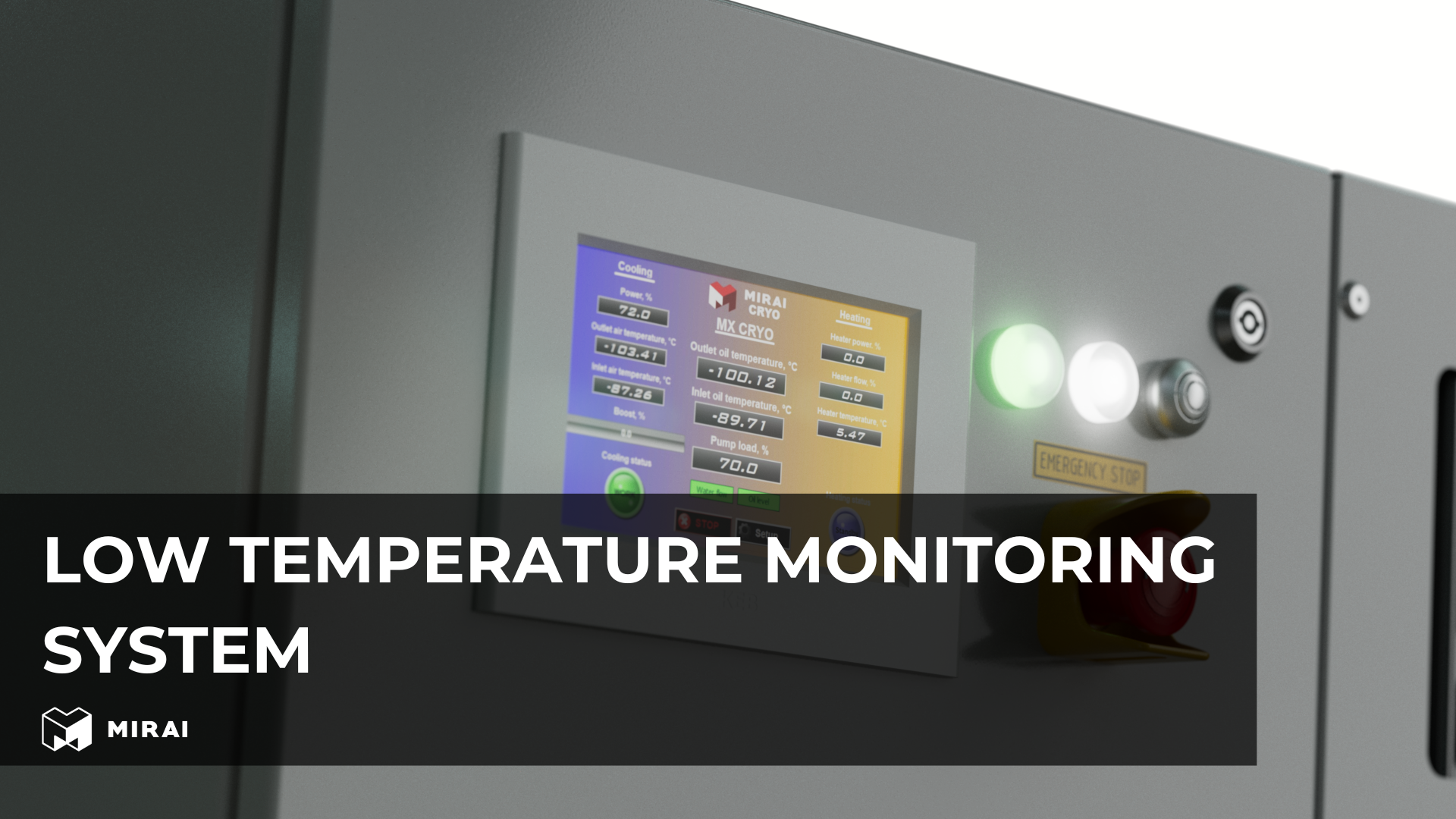

Low temperature monitoring system

Low temperature monitoring systems are critical for maintaining the integrity and safety of various products and environments that require consistent and precise temperature control. These systems are designed to monitor and record temperatures in environments where maintaining low temperatures is essential.

What is a low temperature monitoring system?

A low temperature monitoring system is a setup that continuously monitors and records temperatures in environments that need to be kept at low or ultra-low temperatures. This system ensures that the temperature remains within the required range, alerting users to any deviations that could compromise the safety or quality of the stored products.

Components of a low temperature monitoring system

Sensors

Sensors are the core component of any low temperature monitoring system. They measure the current temperature and convert it into a readable signal. Common types of sensors used include:

- Low temp sensor: Designed to measure temperatures accurately in low temperature environments.

- Cold temperature sensor: Specifically calibrated for cold storage applications.

- Cryogenic sensors: Used for ultra-low temperature applications such as in cryogenic storage.

Alarms

Alarms are critical for alerting users when temperatures deviate from the set range. A low temperature alarm or low temp alarm is triggered when the temperature falls outside the acceptable limits, ensuring timely intervention to prevent damage or spoilage.

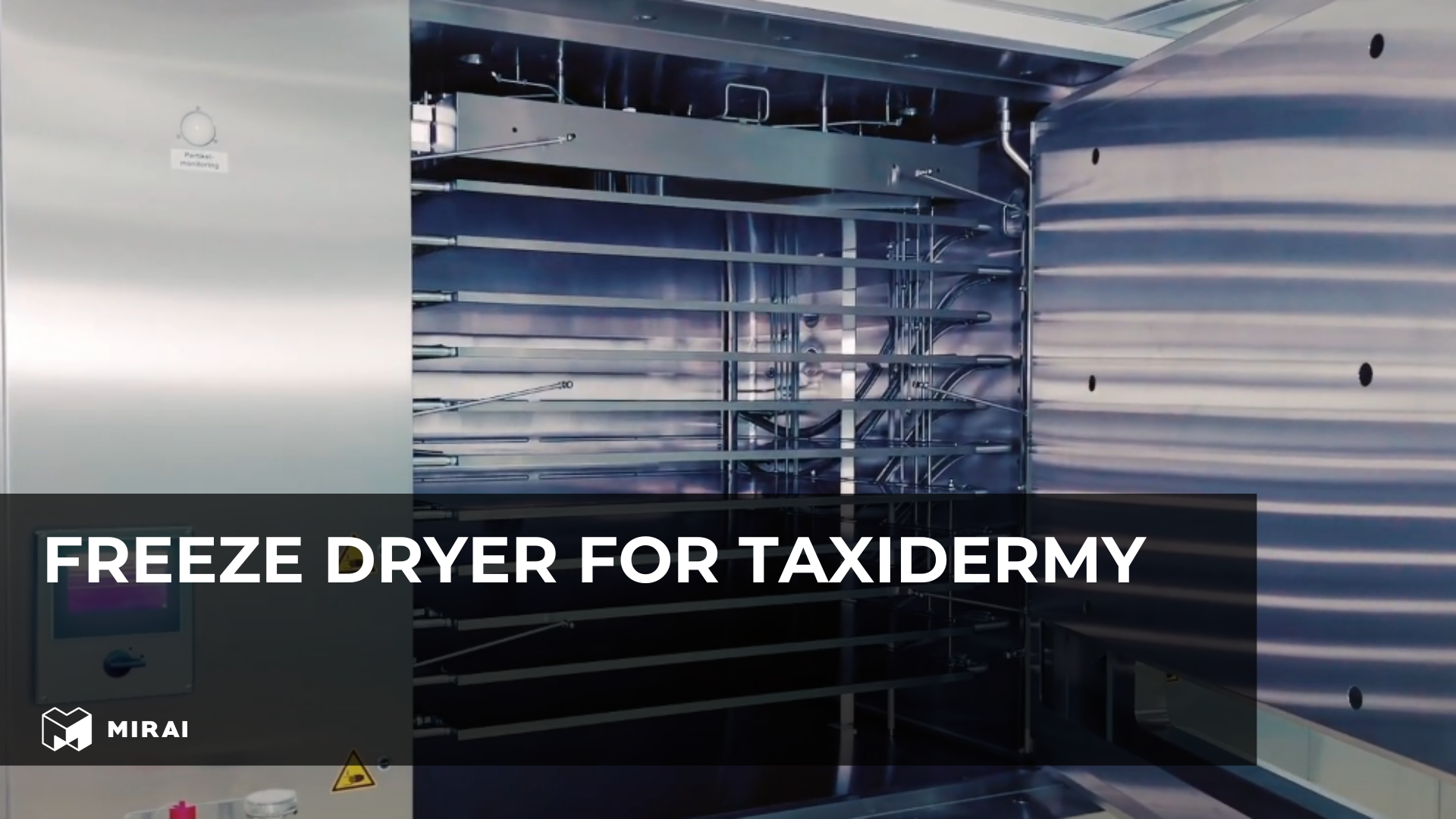

Data display devices

Data display devices show real-time temperature readings. They can range from simple digital displays to complex interfaces that integrate with other systems. These devices often feature data logging capabilities, allowing for the recording and analysis of temperature data over time.

System Types

Low temperature monitoring systems can be categorized into several types based on their complexity and features:

- Basic systems: Include basic sensors and alarms, suitable for smaller applications.

- Advanced systems: Feature data logging, wireless capabilities, and integration with other monitoring systems.

- Cloud-based systems: Utilize cloud technology for remote monitoring and data storage.

- Predictive systems: Incorporate data analytics to predict and prevent potential issues.

Applications

Food Industry

In the food industry, maintaining the cold chain is essential for food safety and quality. Low temperature monitoring systems ensure that food products are stored at the correct temperatures, preventing spoilage and complying with regulatory standards.

Medical

Medical applications, such as the storage of vaccines and other temperature-sensitive materials, rely on low temperature monitoring systems to ensure product integrity. These systems help maintain the required temperatures in freezers and refrigeration units.

Server Rooms

Server rooms require precise temperature control to prevent overheating and equipment failure. Low temperature monitoring systems help maintain an optimal environment for server operation.

Transportation

In the transportation industry, particularly for refrigerated trucks and containers, low temperature monitoring systems ensure that perishable goods are kept at the correct temperatures throughout transit. This is crucial for maintaining the cold chain and ensuring product quality upon arrival.

What MIRAI Intex equipment can be used in monitoring systems

Mirai's equipment can be effectively implemented in transportation containers, laboratory equipment, and cold storage rooms. Here’s how each of these applications benefits from Mirai’s advanced low temperature monitoring systems:

- Transportation containers: Mirai's refrigeration machines implemented in refrigerated transportation containers from Thomaidis are essential for cold chain logistics, transporting temperature-sensitive goods such as pharmaceuticals, food products, and biological samples. By incorporating advanced low temperature monitoring systems, these containers provide real-time data and alerts, ensuring that the cargo remains within the required temperature range throughout the journey, thus maintaining product integrity and safety.

- Laboratory equipment: Mirai offers a variety of refrigeration machines that can be implemented in laboratory equipment. These devices are crucial for research and development activities where precise temperature control is necessary. The integration of low temperature monitoring systems ensures that experimental conditions are consistently maintained, which is vital for accurate and reliable results.

- Cold storage rooms: Mirai's machines in cold storage rooms are designed for large-scale storage solutions used in warehouses,distribution centers, pharma storage, specific vaccine storage, climate testing etc. Advanced temperature monitoring systems are essential in these environments to maintain consistent temperatures across vast spaces. This ensures that all stored goods, such as perishable food items or pharmaceuticals, remain within safe temperature limits, thereby preventing spoilage and ensuring product safety.

By deploying Mirai’s equipment in these areas, businesses can achieve reliable temperature control and monitoring, enhancing the safety and quality of temperature-sensitive products across various industries. Mirai understand the needs and importance of monitoring systems in such areas, therefore offers its clients different types of remote monitoring.

What to rely on when selecting these systems

When selecting a low temperature monitoring system, several factors should be considered to ensure it meets the specific needs of the application:

- Accuracy and reliability: The system should provide precise and reliable temperature readings.

- Data logging and analytics: The ability to record and analyze temperature data is crucial for monitoring and compliance.

- Alarm systems: Effective low temp alarms are essential for timely alerts.

- Integration and compatibility: The system should integrate seamlessly with existing equipment and infrastructure.

- Regulatory compliance: Ensure the system meets all relevant regulatory requirements for the specific industry.

- Predictive maintenance: Systems with predictive maintenance capabilities can help prevent issues before they occur, reducing risk and downtime.

- Cloud-based and wireless capabilities: These features offer flexibility and remote monitoring options, making it easier to manage and maintain the system.

Conclusion

In conclusion, low temperature monitoring systems are indispensable across various industries due to their critical role in maintaining optimal conditions for sensitive products. These systems encompass a range of components and functionalities, each tailored to specific requirements. By carefully assessing your unique needs, you can select a monitoring solution that offers precise temperature control and compliance with regulatory standards.

The integration of modern technologies, such as cloud computing and predictive analytics, has significantly enhanced the performance and reliability of these systems. These advancements provide real-time data access, predictive maintenance capabilities, and comprehensive reporting features, ensuring that your temperature-sensitive assets are consistently protected. As these technologies continue to evolve, they promise even greater accuracy and efficiency, further safeguarding the quality and safety of products in sectors such as food, pharmaceuticals, and biotechnology.

Ultimately, investing in a robust low temperature monitoring system not only ensures compliance with industry standards but also delivers peace of mind, knowing that your critical assets are under constant, vigilant protection.