LIFECYCLE COST ANALYSIS of the MIRAI Cold system

History tends to repeat itself in many ways. When a new technology is introduced, people are usually skeptical when it comes to its proclaimed benefits. Why is the new technology better? Why should it be used instead of the well-proven current technology? Why is it more expensive?

This is only a small sample of questions related to this topic. But the main business question is usually the same: If I use this technology when I can see the benefits (i.e., return of my investment)? For that purpose, Mirai Intex in cooperation with Refolution Industriekälte prepared a lifecycle cost analysis for cold storage solutions. The target is to compare a Vapor Compression System with an Air Cycle System (produced by Mirai Intex). The purpose of this analysis is to find the break-even point of initial investment, running costs, and maintenance costs.

Temperatures Compared

Two ultra-low temperature values were chosen to be compared: -80 °C and -110 °C. Both of these ultra-low temperatures are used for cold storage applications (-80 °C is well known for the COVID-19 vaccine storage) in addition -110 °C application could be also Whole-Body Cryotherapy. Comparing these two temperatures is important in order to understand differences when conventional technology (vapor compression system) is used. For the -80 °C application is customary a two-stage cascade system whereas a -110 °C application would require a three-cascade system. On the other hand, air cycle machines from Mirai Intex (MIRAI Cold) operate from -40 °C down to -130 °C which means both analyzed temperatures are represented by only one machine – in this case, air-cooled MIRAI Cold 15 O/A.

Analysis Presumptions

Following characteristics were established for each refrigeration system to define the typical system:

- The typical vapor compression system is defined as the fixed speed with gas-bypass control

→ vapor compression results are represented only by full load results

- All MIRAI Cold machines are equipped with frequency inverter as standard

→ air cycle results are represented by full load and part load results

Considered costs were defined as following:

- The initial cost is the combination of data and estimation*

- Running costs are measured data**

- Maintenance costs are the combination of data and estimation***

* Average current cost was considered for vapor compression systems based on older equipment cost

** Current EU average prices for electricity used

*** Only estimation can be used for vapor compression systems maintenance in the future with increase prices of refrigerants

Graphic Interpretation of the Results

Based on the fact both technologies are compared the same way, the y-axis value in the chart is considered dimensionless.

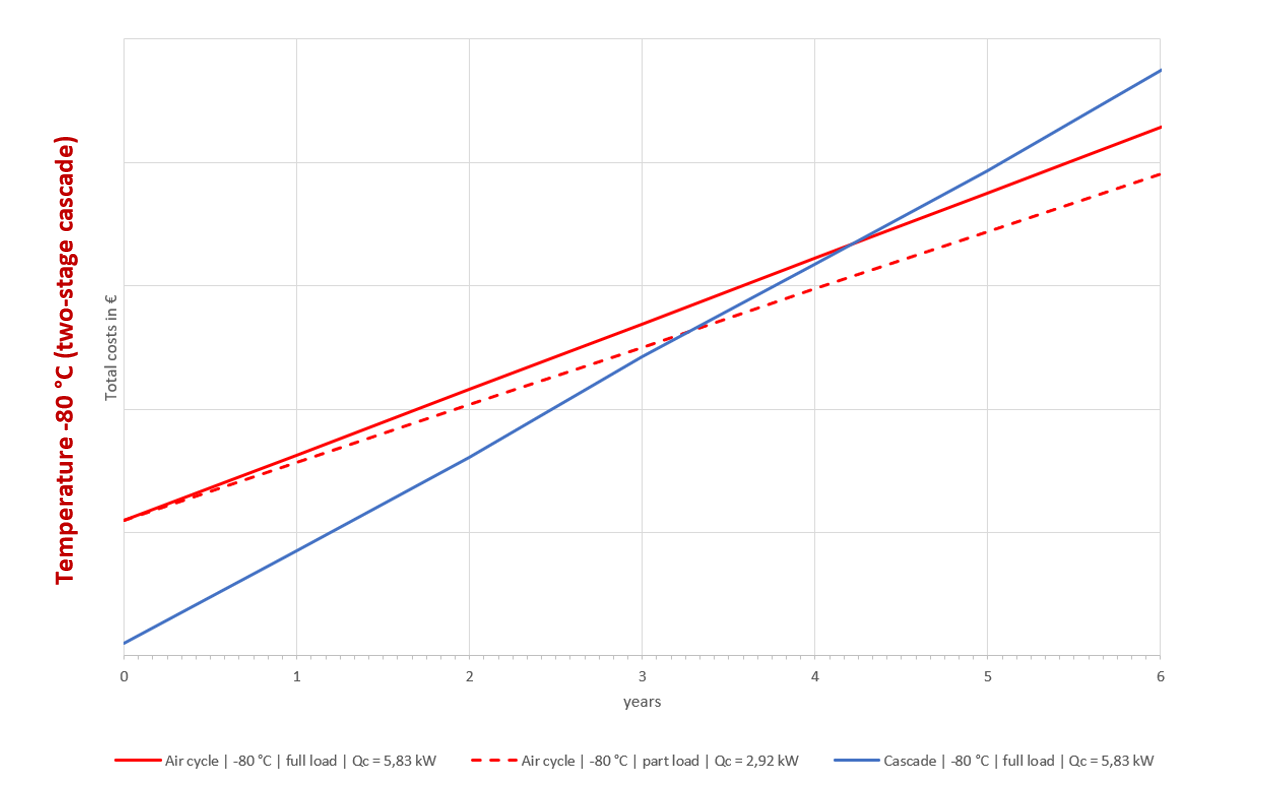

Temperature -80 °C (two-stage cascade)

Temperature -80 °C (two-stage cascade)

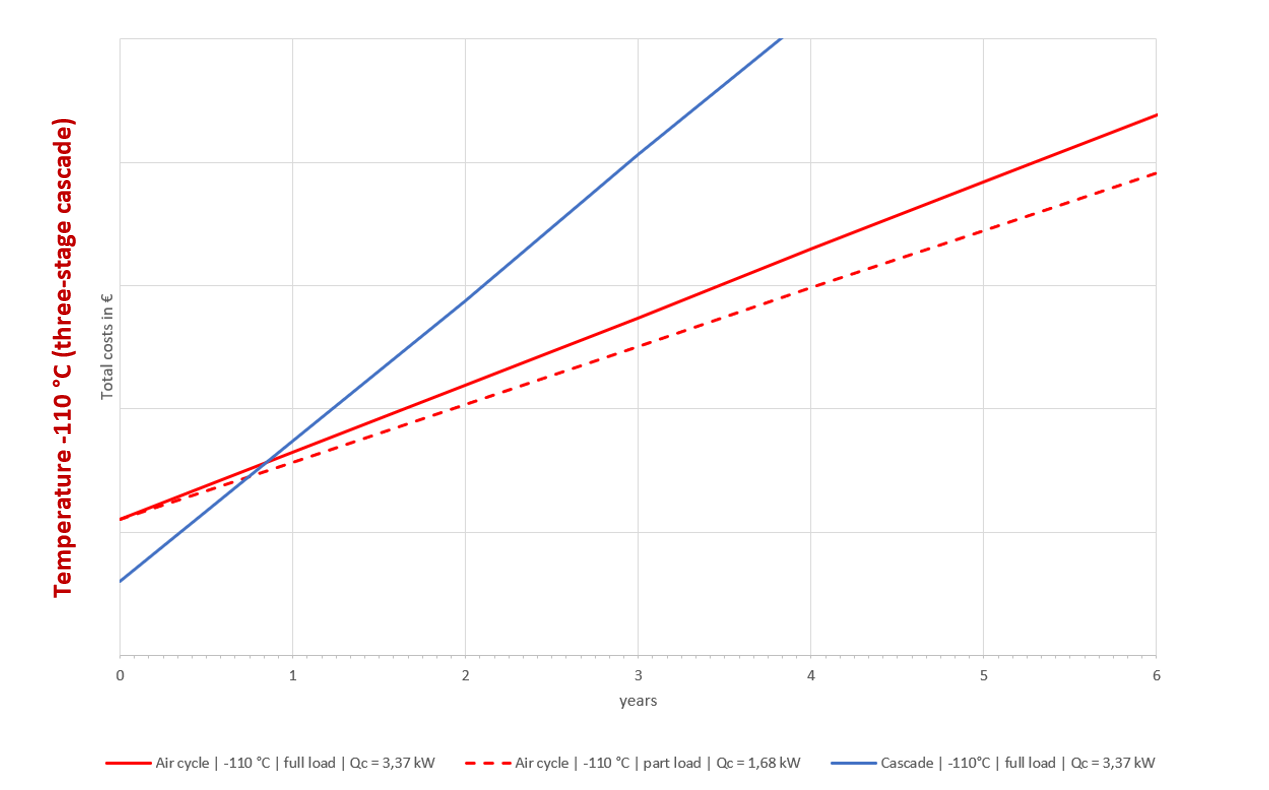

Temperature -110 °C (three-stage cascade)

Temperature -110 °C (three-stage cascade)

Results of Break-Even point -80 °C

Full load break-even: 4 years 3 months

Part load break-even: 3 years 3 months

Results of Break-Even point -110 °C

Full load break-even: 11 months

Part load break-even: 9 months

MIRAI Cold in the field

From experience with projects of our customers, the air cycle technology runs on full load only occasionally. Therefore, the break-even point should be considered mainly for part load data. Another crucial benefit of MIRAI Cold is no need for defrosting procedures consuming additional energy and decreasing cooling efficiency.

Discussion of Results

The main difference in the break-even point for both analyzed temperatures is caused by the different number of cascades. The relatively cheaper option of two-stage cascade makes the initial advantage for the compressor system. On the other hand, the cost of the additional cascade and running costs quickly shows the supreme performance of the air cycle at -110 °C. This shows a simple fact – the lower the temperature the faster return of the investment. Also playing a significant role are increasing prices of energies, refrigerants, and labor creating further disadvantages for cascade systems.

All this is possible because MIRAI Cold refrigeration machines are developed and designed to change the ultra-low temperature refrigeration market for the better bringing benefits such as:

- Air as a refrigerant – free of charge, available, natural, not bound by regulations

- The safest solution on the market – low pressures, no chemicals

- Operates between -40 °C and -130 °C with maximal temperature accuracy and uniformity

- Highly efficient, economical in use, technologically advanced

- No need for defrosting procedures – continuous cooling operation, continuous humidity extraction

- Easy installation and serviceability

- Very low maintenance compared to conventional technology

Note: Break-even point represents model scenario upon specified conditions and real-life values may differ due to factors unable to predict.