Pharmaceutical blast freezing

Pharmaceutical blast freezing is a critical process in the pharmaceutical industry, designed to rapidly freeze pharmaceutical products to preserve their integrity and biological activity. This method is essential for maintaining the quality of heat-sensitive drugs, such as vaccines, biologics, and cell cultures. The main objectives of blast freezing include preventing degradation, ensuring long-term stability, and extending the shelf life of pharmaceutical products. By leveraging advanced industrial blast freezers and air blast freezing technology, pharmaceutical companies can optimize product storage and transportation while complying with stringent regulatory standards.

Principles of Blast Freezing

Blast freezing operates on the principle of rapidly lowering the temperature of pharmaceutical products using high-velocity cold air circulation. This process minimizes the formation of large ice crystals, which can compromise the structural integrity of biological substances. Cryopreservation techniques, combined with precise freeze rate control, help maintain product consistency and prevent degradation. The efficiency of this freezing method depends on various factors, including the type of freezing chamber, the cooling rate, and the use of cryoprotectants to safeguard delicate pharmaceutical ingredients.

Additionally, blast freezing ensures a uniform temperature throughout the product, reducing the risk of localized thawing and re-freezing, which can lead to product instability. The implementation of strict monitoring protocols guarantees that temperature variations are minimized, preserving the active components of pharmaceuticals.

Advantages of Blast Freezing in Pharmaceuticals

Key Advantages of Shock Freezing Over Slow Freezing

There are several key reasons why shock freezing offers significant advantages over slow freezing:

- Formation of More Crystal Nuclei. Shock freezing leads to the formation of a greater number of crystal nuclei compared to slow freezing. As a result, the amount of water available for crystal growth is significantly reduced. In slow freezing, large individual ice crystals form due to competitive crystal growth, as the growth rate of a crystal is proportional to its surface area. The more nuclei present, the lower the chances of large ice crystals developing. However, due to proton mobility within the crystal lattice, recrystallization eventually occurs over time.

- Slowing Down Chemical Reactions. Shock freezing effectively slows down chemical reactions such as autolysis and fermentation. According to Van’t Hoff’s Rule, the rate of chemical reactions decreases as the temperature drops. The faster the cooling process, the slower the degradation of the product, preserving its quality for a longer period.

- Oxidation of Fats and Cold Sublimation. Frozen ice in the form of ice needles can reach sizes of 180 microns or more, significantly exceeding the diameter of muscle fiber cells. These ice crystals puncture cell membranes, and over time, recrystallization occurs during storage. Ice crystals in contact with each other merge into a porous structure, occupying the entire volume of the product. As a result, sublimation begins, leading to moisture loss and creating open pathways for oxygen penetration. This exposure causes fat oxidation and rancidity.

- To prevent sublimation, the food industry employs glazing techniques. Shock freezing has the advantage of delaying the onset of sublimation until the third or fourth month of storage, whereas regular freezing triggers sublimation almost immediately. This delay occurs because the recrystallization of the smaller ice crystals formed during shock freezing happens later, postponing the onset of active sublimation.

- Deformation Changes in the Product. Rapid freezing causes deformation in the product due to the difference in density between ice and water. A useful analogy can be drawn from furniture manufacturing, where a chair leg must be bent slowly to avoid breaking. Similarly, slowing down deformation improves the quality of frozen products. Contrary to the common belief that faster freezing always results in better quality, research by Wenger demonstrates that an increase in freezing speed can actually degrade product quality.

Applications of Blast Freezing in Pharmaceuticals

- Freezing of Biopharmaceuticals: Vaccines, serums, and monoclonal antibodies require controlled freezing conditions to maintain their efficacy and stability. The proper preservation of these biologics is crucial in combating infectious diseases worldwide.

- Preservation of Cell Cultures and Tissues: Cryopreservation techniques ensure that valuable biological samples, such as stem cells and tissue cultures, remain viable for future medical and research applications. Proper freezing techniques prevent cellular damage and maintain biological integrity.

- Freezing of Active Pharmaceutical Ingredients (APIs): Industrial blast freezers are used to stabilize APIs, preventing premature degradation and ensuring product consistency. APIs require controlled storage conditions to maintain their chemical properties and ensure effectiveness in drug formulations.

- Preparation of Drugs for Lyophilization: Flash freezing is a crucial preparatory step in the lyophilization process, where water is removed from pharmaceuticals to enhance their stability and shelf-life. Proper freezing before lyophilization prevents structural collapse and maintains drug efficacy.

Blast Freezing Equipment

Types of Freezing Chambers:

- Contact Freezing Devices: These systems use direct contact with cooling plates to achieve rapid freezing, commonly used for small-scale applications.

- Air Blast Freezers: High-powered fans circulate ultra-cold air to freeze products uniformly, making them ideal for large-scale pharmaceutical applications.

Technological Features:

- Temperature Range: Maintaining ultra-low temperatures ensures effective preservation of pharmaceutical products.

- Freeze Rate Control: Adjustable cooling speeds allow for customized freezing protocols based on specific product requirements.

- Energy Efficiency and Reliability: Advanced industrial blast freezers are designed for minimal energy consumption while delivering high-performance cooling.

- Role of Automation in Modern Systems: Automated monitoring and control systems enhance consistency, ensuring compliance with regulatory requirements.

- Cryogenic Freezing Methods: Some systems utilize cryogenics to achieve even lower temperatures, crucial for certain sensitive pharmaceuticals.

- Real-time Monitoring: Integrated temperature sensors provide continuous feedback to maintain optimal freezing conditions.

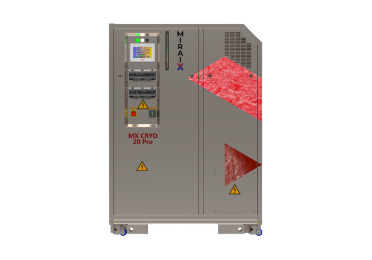

MIRAI Products in Pharmaceutical Blast Freezing

MIRAI INTEX offers cutting-edge refrigeration machines for blast freezing solutions that enhance the efficiency and reliability of the freezing process. Our industrial refrigeration machines are designed to maintain stringent temperature controls, ensuring pharmaceutical products remain stable and effective.

Our refrigeration solutions provide precise temperature regulation, preventing the degradation of sensitive biological materials, vaccines, and active pharmaceutical ingredients (APIs).

MIRAI’s innovative refrigeration machines utilize energy-efficient, eco-friendly refrigeration technologies, reducing operational costs while maintaining superior freezing performance. Designed to meet the demands of pharmaceutical manufacturers, research laboratories, and biotech firms, our systems offer customizable configurations to accommodate different freezing requirements.

MIRAI INTEX is also proud of its wide range of refrigeration solutions, including both Open and Closed cycle machines, designed for various cooling and freezing needs. These solutions ensure efficient and reliable operation in different technological environments and industries.

In addition to high-performance freezing solutions, MIRAI INTEX offers the MIRAI X CRYO line – innovative systems capable of not only cooling but also heating. At the same time, MIRAI X CRYO delivers ultra-deep cooling, which is a hallmark of MIRAI INTEX, ensuring precise and reliable temperature control. This advanced technology minimizes the risk of thermal stress, preserves the integrity of pharmaceutical products, and enhances efficiency across all stages of processing.

Requirements and Standards

Regulatory Guidelines:

- Good Manufacturing Practice (GMP): Compliance with GMP ensures that freezing processes meet the highest quality and safety standards.

- International Pharmacopoeias: Adhering to global pharmaceutical standards guarantees consistency and reliability in freezing operations.

- Sanitary and Hygienic Standards: Proper equipment maintenance and cleanliness are crucial for preventing contamination and ensuring product integrity.

- Control and Documentation of Freezing Processes: Monitoring systems track temperature fluctuations, ensuring that pharmaceutical products are stored under optimal conditions. Compliance with regulatory protocols involves detailed inspection and documentation to verify process consistency.

Conclusion

Pharmaceutical blast freezing is an indispensable process for maintaining the quality and stability of pharmaceutical products. By utilizing advanced freezing technology, including air refrigeration machines and industrial blast freezers, companies can enhance product preservation, ensure regulatory compliance, and optimize storage and transportation conditions. MIRAI INTEX continues to lead the way in providing high-efficiency refrigeration machines ensuring the safety and efficacy of essential medical products worldwide.

As the pharmaceutical industry evolves, continuous improvements in blast freezing technology will further enhance efficiency, sustainability, and product integrity. Innovations in cryopreservation, automation, and energy-efficient cooling systems will contribute to reducing pharmaceutical waste while ensuring the delivery of high-quality medications to patients worldwide.