Cooling technology

Cooling technology, defined as the science and engineering behind managing temperatures in machinery and systems, plays a critical role in modern life. At its core, a cooling system works by circulating a coolant through a circuit of components designed to remove heat. This process is fundamental in preventing overheating in critical applications, cool processes, places from automotive engines to complex industrial machinery. The main parts of a typical cooling system include the coolant, pump, radiator, and a series of engineered cooling products that ensure efficient heat exchange. Through the application of principles from thermodynamics, these systems maintain optimal operation temperatures, ensuring the longevity and performance of machines and devices across various sectors.

Classification of refrigeration technologies

Cooling technology can be classified based on the type of refrigerant used or the construction approach. This classification includes air cooling, liquid cooling, and phase change systems, each with distinct principles, components, and applications.

Air Cooling employs air as its refrigerant, making it a widely adopted solution in various applications due to its cost-efficiency, reliability, and environmental friendliness. The operational principle hinges on channeling ambient air through a radiator, effectively dissipating heat from the system. Key components include the radiator, which serves as the heat exchanger, the fan, responsible for propelling air over the radiator, and the compressor, which orchestrates airflow for maximum efficiency. This approach's simplicity not only minimizes upfront costs but also reduces maintenance expenses, enhancing its reliability. Moreover, by utilizing air—a naturally abundant and non-polluting refrigerant—air cooling systems underscore a commitment to environmental sustainability. This method is particularly favored in many applications.

Liquid Cooling, on the other hand, uses a liquid coolant to absorb and remove heat. The principle of operation involves circulating the coolant through a water block attached to the heat source, then through a radiator where heat is released to the atmosphere. Essential components include the water block for direct contact with the heat source, the pump for circulating coolant, the radiator for heat exchange, the reservoir for holding excess coolant, and tubes that connect these parts. Liquid cooling is preferred for its superior cooling efficiency, particularly in high-performance computing and automotive applications.

Phase Change systems work by exploiting the heat absorption or release during the refrigerant's phase transitions between liquid and gas. This process involves evaporation, where heat is absorbed by the refrigerant, and condensation, where heat is released. Key components include the evaporator, where the refrigerant absorbs heat and evaporates; the condenser, where the gaseous refrigerant condenses, releasing heat; and the compressor, which circulates the refrigerant through the system. Phase change cooling is used in refrigeration and air conditioning, offering high efficiency in heat transfer.

By type of construction

Cooling technology is broadly categorized into active and passive systems based on construction type, each serving distinct functions with specialized components.

Active Cooling employs mechanical or electronic methods to move heat away from devices, using fans, pumps, and compressors to circulate coolant. This approach is essential for managing high thermal loads in applications like high-performance computing and automotive systems, where maintaining optimal temperatures is crucial for efficiency and reliability. Active cooling systems are characterized by their quick response and ability to handle significant heat dissipation needs.

Passive Cooling, on the other hand, relies on natural processes such as convection and radiation, without the need for energy-consuming components. Heat sinks, thermal pads, and phase change materials are common in passive setups, offering silent operation and fewer mechanical failures. This method is favored for its energy efficiency and sustainability, ideal for low-power devices and eco-friendly building designs.

Advantages and disadvantages of each technology

Air Cooling

Advantages:

- Cost-effectiveness. Air cooling offers a high performance-to-cost ratio, making it an accessible option for a wide range of users.

- Simplicity and reliability. With fewer moving parts and no liquids involved, air coolers are straightforward to install and maintain, offering a reliable cooling solution with minimal risk of failure.

- Ease of maintenance. Air cooling systems require less upkeep than their liquid and phase change counterparts. There's no need to worry about coolant levels, leaks, or complex maintenance routines.

- Good performance. For the majority of computing tasks, including gaming and everyday use, high-quality air coolers provide more than adequate cooling efficiency, ensuring optimal performance and longevity of components.

- No government regulations. Air-cooling has another significant advantage, it uses air, so it is not affected by any introduction of refrigerant quotas like F-gas regulation.

Disadvantages:

- Physical size: High-performance air coolers can be large, potentially causing compatibility issues with smaller cases or tight builds. But modern air-cooled manufacturers like MIRAI Intex have solved this problem. The size of their machines is relatively small, with incredible efficiency.

- Noise levels: Fans may become noisy under load, although this can be mitigated with modern, high-quality fans designed for quiet operation. But there is also already a solution to this problem. Many air-cooling manufacturers are quieter than their counterparts with other types of cooling.

Liquid Cooling

Advantages:

- Efficient cooling: Liquid cooling is efficient for heat removal, particularly in compact or high-performance setups. However, for many users, the performance benefit does not justify the additional complexity and cost.

Disadvantages:

- Complexity and maintenance: Requires more setup and maintenance effort, with the added worry of potential leaks damaging components.

Phase change cooling

Advantages:

- Extreme cooling: Offers unparalleled cooling capabilities for extreme overclocking, far beyond what most users require for daily tasks or gaming.

Disadvantages:

- High cost and complexity: The cost and complexity of phase change systems place them beyond the practical reach of most users and into the realm of niche applications.

In comparison, air cooling stands out for its unbeatable combination of cost-effectiveness, simplicity, and reliability. Air cooling strikes an optimal balance between performance, affordability, and ease of use.

Applications of cooling technologies

Different cooling technologies find their application in a multitude of sectors from small businesses to industrial scale for different purposes. Pharmaceutical companies use refrigeration at nearly every stage of interaction with vaccines, from transportation, to storage. The medical sector, logistics, energy recycling, camera testing, chip manufacturing, vacuum drying,power generation units, food transportation, processing and storage, drying, chemical processes, material recycling, freezing of all materials that exist in nature and much more. Even the eyeglasses that many of us wear are sprayed using cooling.

Each sector has its own specific requirements in terms of temperature control, temperature range, noise and vibration during operation, refrigerant, price, etc. Therefore, each process must be carefully selected to determine which type of refrigeration is best.

The Future of Cooling Technology

The future of cooling technology is set for transformative advancements, becoming more efficient, eco-friendly, and smarter. With increasing demands from sectors like computing and automotive, innovations will focus on advanced materials and AI integration for superior heat management and efficiency. The development of eco-friendly refrigerants and use of natural refrigerants, increased demand for those types of refrigerants and passive cooling strategies will address environmental concerns, reducing the carbon footprint of cooling operations. Cooling technology will continue to play a crucial role in enabling the next generation of electronic devices, vehicles, and machinery, ensuring they operate reliably and efficiently in an increasingly tech-driven world.

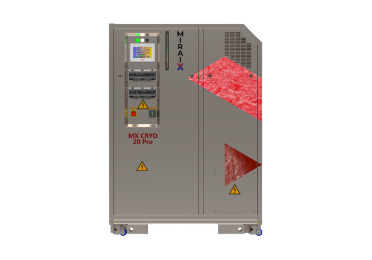

Mirai Cooling Systems

MIRAI Intex is at the forefront of air-cycle cooling technology, setting new standards with their innovative approach. MIRAI have developed a unique system for low and ultra-low temperature applications, relying entirely on air to cool. This means the cooling machines are environmentally friendly, using no harmful chemicals as refrigerants. Impressively, the technology runs smoothly without any vibration and keeps noise levels extremely low during the operation, making it ideal for applications where silence is golden.

One of the standout features of MIRAI Intex's technology is the turbo compressor, which is a game-changer. It's engineered to last for two decades without needing much maintenance, a testament to its durability and quality. This aspect is particularly appealing, as it reduces the hassle and cost of frequent service checks.

These cooling systems are designed to be versatile, able to replace older cooling technologies easily. They're also flexible enough to be used in a variety of industries for different purposes, from small businesses to large manufacturing plants, demonstrating their wide applicability.

MIRAI Intex's commitment to innovation, sustainability, and reliability makes their air cycle solutions a top choice for businesses looking to upgrade their cooling systems without the environmental footprint of traditional methods,green solutions for today’s thermal management challenges.

Trends in refrigeration technology

Trends in refrigeration technology are marked by significant advancements aimed at enhancing efficiency, reducing environmental impact, and improving system intelligence.

Development of new refrigerants and use of natural refrigerants

With more and more regulations and restrictions on the use of harmful refrigerants, the creation of alternative refrigerants and the use of natural refrigerants such as air and CO2, propane, and ammonia has become a growing trend. These new approaches of coolant systems, promising greener operation without sacrificing performance.

Improved cooling system design

Engineered cooling products are witnessing a revolution in design, optimizing for better heat exchange, reduced energy consumption, and compactness. Improved system designs incorporate advanced materials and innovative components configurations, enhancing the overall efficiency and reliability of refrigeration systems.

Use of artificial intelligence (AI)

AI is becoming integral to cooling technology, enabling smarter coolant systems that can predict thermal loads, adjust operation parameters in real-time, and optimize energy use.

Together, these trends indicate a future where refrigeration technology not only becomes more sustainable and efficient but also smarter, adapting to the needs of a wide array of applications from automobiles to industrial machinery.

Frequently asked questions on the topic

Is cold temperature bad for electronics?

Generally, electronics operate efficiently in cooler environments, as cold temperatures help prevent overheating and reduce thermal stress on components. However, extremely cold temperatures can be harmful, leading to issues like condensation inside devices, which can cause short circuits or corrosion. It's important to keep electronics within their recommended operating temperature range to ensure optimal performance and longevity.

What is hybrid cooling technology?

Hybrid cooling technology combines two or more cooling methods, such as air and liquid cooling, to optimize thermal management in electronic devices or systems.

What is the most efficient type of cooling?

The most efficient type of cooling often depends on the specific application and environment, but generally, air cooling is considered more efficient and reliable nowadays.