Chiller Types and Applications: Industrial & Ultra-Low Temperature Guide

Chiller Types and Applications: Industrial & Ultra-Low Temperature Guide

Engineers and facility managers need to make a smart technical and financial choice when it comes to cooling systems. This option might have huge impacts in the long term. Picking the wrong chiller types might do more than just waste electricity. They can also make the product worse, make the process less reliable, cause more downtime, and raise the overall cost of running the business. If a process cooling system breaks down, it can stop a production line, spoil a batch of medications, make essential research useless, or break expensive equipment.

It's crucial to know the difference between typical HVAC comfort cooling, which is largely about making buildings comfortable, and the more intricate and specific needs of industrial process cooling. This article is about industrial chillers that are designed for use in labs, factories, and other technological settings. We will talk about the numerous types of chillers that perform best for these jobs, with a focus on low-temperature chiller types. We will also discuss the special thermodynamic, mechanical, and regulatory challenges that happen when the temperature drops below -40°C, when normal cooling methods generally don't function well. You need to know about these distinctions and technologies so that you may be sure that a system will perform properly, be cost-effective, and obey the laws in the future.

What Is a Chiller and Where It Is Use

In engineering terms, a chiller is a machine that removes heat from a fluid (typically water or a glycol mixture) via a vapor-compression or absorption refrigeration cycle. This chilled fluid is then circulated to absorb unwanted heat from a process or space. The application defines the chiller's design. Comfort cooling for buildings and HVAC prioritizes energy efficiency at moderate temperatures (e.g., 6-12°C supply). In contrast, process cooling for industry, medical, or laboratory use demands precise, reliable, and often extreme cooling for machinery, experiments, or production lines, making the selection among various industrial chillers paramount.

Main Chiller Classifications

There are a few main technological axes along which chiller types can be grouped: the type of refrigeration system (vapor-compression or absorption), the way heat is removed (air-cooled chiller or water-cooled chiller ), the type of compressor used, the desired temperature range, and the specific use. The first step in finding your way around the huge world of industrial chillers is to understand these groups.

Classification by Refrigeration Principle

At the core of any chiller type is its refrigeration cycle. The two primary principles are vapor compression (mechanical) and absorption (thermal).

Vapor Compression Chillers

This leading technology uses a compressor that is operated by a motor to move refrigerant around. The refrigerant turns from a liquid to a gas and back again to take in and give out heat. Because it is efficient, easy to manage, and can handle a wide range of capacities, it is the most important part of most industrial chillers. But as temperatures drop below -60°C, single-stage vapor compression becomes much less effective, and specialized designs or cascaded systems are needed. This shows how limited this method is for very low temperatures.

Absorption Chillers

When you utilize an absorption chiller, you employ a heat source, like waste steam or hot water, to power the refrigeration cycle. A chemical solution acts as the absorbent. They are mostly useful in cogeneration (CHP) facilities or places where there is a lot of waste heat. They have some problems, including reduced electrical efficiency, slower reaction and control precision, and practical limits that make them not good for low-temperature chiller types, especially in the ultra-low range.

Classification by Heat Rejection Method

Once heat is absorbed from the process, the chiller must reject it to the environment. The method significantly impacts system design, efficiency, and location.

Air-Cooled Chillers

An air-cooled chiller uses air from the outside to blow over a condenser coil to get rid of heat. They are self-contained devices that don't need a separate cooling tower.

|

Pros |

Cons |

|

Easier to install, no cooling tower |

Less efficient, especially in warmer weather |

|

Less water use and expense |

Larger footprint for for the same amount of space |

|

Easier maintenance (no water treatment) |

Higher operating noise level |

Typical Use: Rooftop installations, places with little water, and industrial chillers with a medium capacity.

Water-Cooled Chillers

A water-cooled chiller transfers heat to a condenser water loop, which is subsequently cooled in a different cooling tower.

|

Pros |

Cons |

|

More consistent performance and higher efficiency |

Needs a cooling tower and a mechanism for treating water |

|

Longer lifespan (more gentle working circumstances) |

More complicated and expensive to install at first |

|

Less space needed for a large chiller |

It all depends on how much water is available and what chemicals are used to treat it. |

Typical Use: Large-capacity facilities, applications with a lot of heat, and inside installations of important industrial chillers.

Classification by Compressor Type

The compressor is the core of vapor-compression chiller types, defining their capacity, efficiency, temperature range, and maintenance needs for various industrial chillers.

Scroll Compressors

Scroll chillers are modest, reliable equipment that work best at normal temperatures and for small to medium-sized jobs. Their basic design means they don't need much maintenance, but their limited displacement and pressure ratio make them not good for very low temperature chiller applications.

Screw Compressors

The screw chiller is a very useful type of industrial chiller that can handle a wide range of loads and has great capacity control. But it needs complicated oil management, and its efficiency goes down when the pressure ratios are high enough for deep low temperature chiller operation.

Centrifugal Compressors

Centrifugal chillers are particularly efficient at cooling very large loads, often in the megawatt range. Their main problem is that they only work in a small range of conditions. They tend to surge when the load is low or the pressure ratio is high, which makes them useless for very low-temperature tasks.

Magnetic Bearing Compressors

These oil-free compressors are easier to maintain and work better at partial loads since they use frictionless magnetic levitation. Crucially, they are not refrigerant-free—they still use regulated F-Gas refrigerants and face the same low-temperature thermodynamic limits as other vapor-compression systems.

Air Bearing Compressors

Air bearing compressors are a type of oil-free technology that uses a pressured air film to make contact-free spinning. Like magnetic bearings, this gets rid of the need for oil-related maintenance, but it doesn't get rid of the need for refrigerant or the basic problems of getting very low temperatures in a vapor-compression cycle or need of magnetic calibration.

.png)

Refrigerants and Regulatory Constraints

Regulatory pressure on refrigerants is a key design consideration that affects how long a system lasts, how much it costs to own, and how well it meets environmental standards.

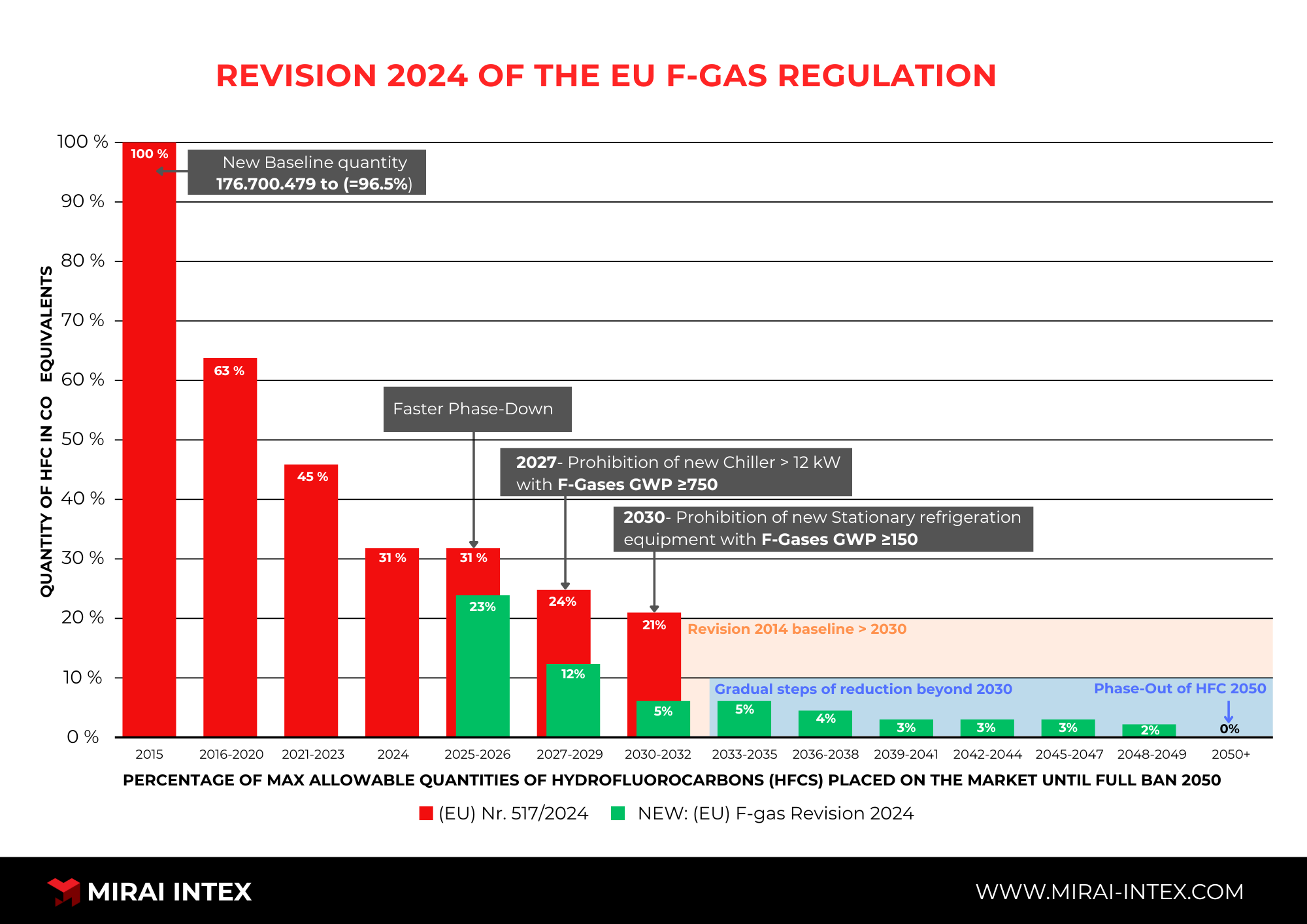

High-GWP Refrigerants and F-Gas Risk

Hydrofluorocarbon (HFC) refrigerants like R404A, R452A, or R23 are used in many low-temperature chiller types. These refrigerants have a very high Global Warming Potential (GWP). The EU F-Gas Regulation and comparable rules around the world are phasing out these refrigerants. This is causing prices to go up, making them harder to get, and putting systems that rely on them at long-term risk.

Natural Refrigerants vs Air

Natural refrigerants like CO₂ (R744) or hydrocarbons (e.g., R290) have a low GWP, but they also have some downsides. CO₂ works at very high pressures, and hydrocarbons can catch fire (A3 safety class). In some temperature ranges, they also become less effective. Using "air" as a refrigerant (in air-cycle systems) is a completely different option that doesn't need any rules. We'll talk about it next.

Air-Cycle Refrigeration as an Alternative

Air-cycle refrigeration technology is a new form, not just a different kind of vapor compression. Both systems may use a compressor, but they work in quite different ways, with different principles, working fluids, and methods. Traditional vapor-compression chillers use a controlled chemical refrigerant that may change from a gas to a liquid and back again to absorb and release heat. Air-cycle systems, on the other hand, just need compressed air from the outside world to work. The Joule-Thomson effect says that when you quickly let compressed air out, it cools down. This method skips the whole process of handling refrigerants, regulating phase transitions, and following environmental rules. This is what sets air-cycle technology apart from other types of industrial chillers. This is especially vital for low-temperature chiller types operations, when keeping things clean, reliable, and as safe as possible from regulatory hazards are all very important.

How Air-Cycle Chillers Differ from Conventional Systems

Air-cycle systems use the air around us as the working fluid instead of refrigerants that change phases. This is a major difference from the intricate thermodynamics that happen when things turn into gas and back into liquid. In a closed-loop Brayton or reverse Brayton cycle, an intercooler or aftercooler cools down the air and compresses it. A cooling tower or a normal water-cooled chiller is typically used for this. After that, the cooled, high-pressure air quickly expands through a turbine in an isentropic method. This expansion changes the air's internal energy into shaft work and kinetic energy, which decreases the temperature by a very big and exact amount. It is significantly different from other chiller types, including cascade systems that are hard to set up and need more than one refrigerant, compressor, and oil circuit to reach the same temperatures. These systems can go as cold as -100°C or lower in one intense stage.

There are a lot of strategic benefits to this simple idea. First of all, it gets rid of all the rules and problems that come with high-GWP fluorinated gases (F-Gas). These include expensive cuts, testing for leaks, and the chance that there won't be enough refrigerants in the future. Second, it gets rid of the requirement for complicated oil separation and management systems. These systems are a significant reason why screw chiller and scroll chiller units have trouble with maintenance and may get dirty. It's easy to grasp the key pieces of the system: a compressor, heat exchangers that take heat away, and an expansion turbine. This design makes it less likely to break down and easier to fix using standard mechanical methods. Because of its natural simplicity and purity, this technique is great for particularly delicate ultra-low temperature operations in the food processing, biotech, and pharmaceutical industries, where keeping the product pure is very critical.

For some industrial chillers and low-temperature chiller types, air-cycle technology is not simply an option; it's also a critical strategic technology. It focuses on the critical connection between developing standards for the future that require performance at very low temperatures and the need for operations in important processes that are clean, reliable, and easy to maintain. It gives engineers a whole new and powerful approach to cool things down that they can utilize for the next ten years and longer.

Typical Industrial Applications

Different industries require specific temperature ranges and reliability levels. Selecting from the correct chiller types is application-specific.

|

Application |

Temperature Range |

Typical Chiller Type Considerations |

|

Medical & Pharmaceutical Cooling |

+2°C to -50°C |

High reliability, hygienic design, validation support. |

|

Freeze-Drying & Lyophilization |

-60°C to -90°C |

Stable, precise shelf temperature control for product quality. |

|

Plasma & Biostorage |

-60°C to -80°C |

Uniform Blood plasma freezing systems rates, ultra-low temperature stability for preservation. |

|

Semiconductor & Testing |

+90°C to -120°C |

Precise, rapid, and repeatable temperature cycling for R&D and testing. |

Medical & Pharmaceutical Cooling

These industrial chillers need to be completely reliable for MRI machines, CT scanners, and labs. It is not up for debate that cleanliness, following the rules for medical devices, and exact control are all important for Cold Chain in the Pharmaceutical.

Freeze-Drying & Lyophilization

The primary and secondary drying phases need plate temperatures that are both stable and accurate. Inconsistent cooling from a low temperature chiller can directly impact product structure and drying time.

Plasma & Biostorage

To keep cells from being damaged, blood plasma or biological samples must be frozen at the same pace. Storage then needs to be stable at very low temperatures, which is usually done by cascade refrigerant systems or air-cycle units.

Semiconductor & Testing

Environmental test chambers, wafer etching, and component testing need quick pull-downs and exact control at very high and low temperatures, which is too much for most chiller types.

How Mirai Intex Fits into Modern Chiller Architectures

Mirai Intex is an OEM technology vendor that focuses on adding air-cycle cooling modules to bigger systems. That offers a basic chiller replacement but comes with a core cooling engine that is designed on a better technological base.

Air-Cycle Units as Part of Larger Systems

Our air-cycle modules are high-tech, self-contained construction blocks that are made to fit together perfectly. They are the best way to get around the problems with regular chiller types, especially for applications that need chillers that work at very low temperatures. Because of their built-in benefits, system architectures can be versatile and powerful:

Direct Retrofit for Strategic Upgrades: You may directly retrofit our modules into your current systems to replace old, inefficient, or regulated refrigerant-based units. This exchange protects your business against F-Gas liability and cuts down on maintenance expenses right away. It also makes important processes far more reliable.

The Ultimate Low-Temperature Stage: Our technology is the best at the ultra-low temperature stage for complicated cooling tasks that need a wide temperature range. It uses air to handle the hardest part of deep cooling (from +90°C to -160°C and lower), which means that higher-temperature stages can employ simpler, more efficient fluids. This design makes the whole system as efficient and reliable as possible.

Mirai Intex works with OEMs to fully integrate our air-cycle core into new equipment like freeze-dryers (lyophilizers), environmental test chambers, semiconductor process tools, and specialized industrial chillers. This gives equipment makers a huge edge over their competitors: they can sell items that are cleaner (free of oil and refrigerant), more reliable, meet all existing and future requirements, and work better at low temperatures than anything else.

Mirai Intex technology doesn't simply fit into modern structures; it defines the future generation of reliable, sustainable, and high-performance cooling for industry by delivering a cooling engine that doesn't need refrigerants, is immune to regulations, and is structurally strong.

.png)

How to Choose the Right Chiller Type

This list can help you make a choice:

- What temperature does the supply need to be? If the temperature is below -60°C, you might choose to use cascade systems or air-cycle technologies.

- Load Profile: Does the load stay the same or does it change? Does it need to cycle quickly?

- Regulatory Future-Proofing: How much risk does the refrigerant you chose pose in the long term with F-gas regulation? Are there any other rules in your market?

- Energy Efficiency: Consider both the IPLV for full load and portion load.

- What are the local service skills and knowledge for handling oil, refrigerants, or specific expanders?

- Lifetime Cost: Look at the cost of the capital, the energy it uses, the cost of maintenance, the cost of refrigerant, and the cost of decommissioning at the end of its life.

- Scalability: Can you easily add to the system or link it to a bigger one?

Conclusion

Selecting from the wide array of chiller types for tough industrial and low-temperature jobs is a big decision that will affect how well they work in the long term. Standard air-cooled chiller or water-cooled chiller systems work well enough for most situations, and reliable screw or centrifugal chiller units can handle heavy industrial needs. But the future for demanding industrial chillers is with new technologies that can handle rules and regulations.

This technology is at the cutting edge of air-cycle refrigeration. This new technology uses air as the refrigerant, which means it's ready for the future. This stylish method does away with the need for regulated synthetic refrigerants and complicated oil systems. It keeps things very cold and clean, and it works very well.

Air-cycle technology is more than just another option for engineers who care about sustainability, reliable operations, and long-term value. It is the clear next-generation solution that turns your cooling system into a long-term strategic asset.

To discuss how air-cycle technology can integrate into your specific application or to request technical information, contact our engineering team.