Life cost analysis 2022

We are living through an unprecedented time in our lives. Being used to availability of goods and resources, our economies and businesses have thrived. Unfortunately, that is no longer the case, especially in Europe. With the reduction of energy supply and the subsequent dramatic price increases, energy efficiency becomes one of the most important aspects when choosing an air conditioner, a car, or even an Ultra-low temperature refrigeration machine!

Mirai Intex supplies the most efficient refrigeration machines for Ultra-low temperature applications, but we wanted to know, what is the overall economic effect of our systems efficiency and low maintenance requirements compared to standard two cascade systems that run with high GWP HFCs such as R404A and R23, and three cascade systems that run with R404A, R23 and R14.

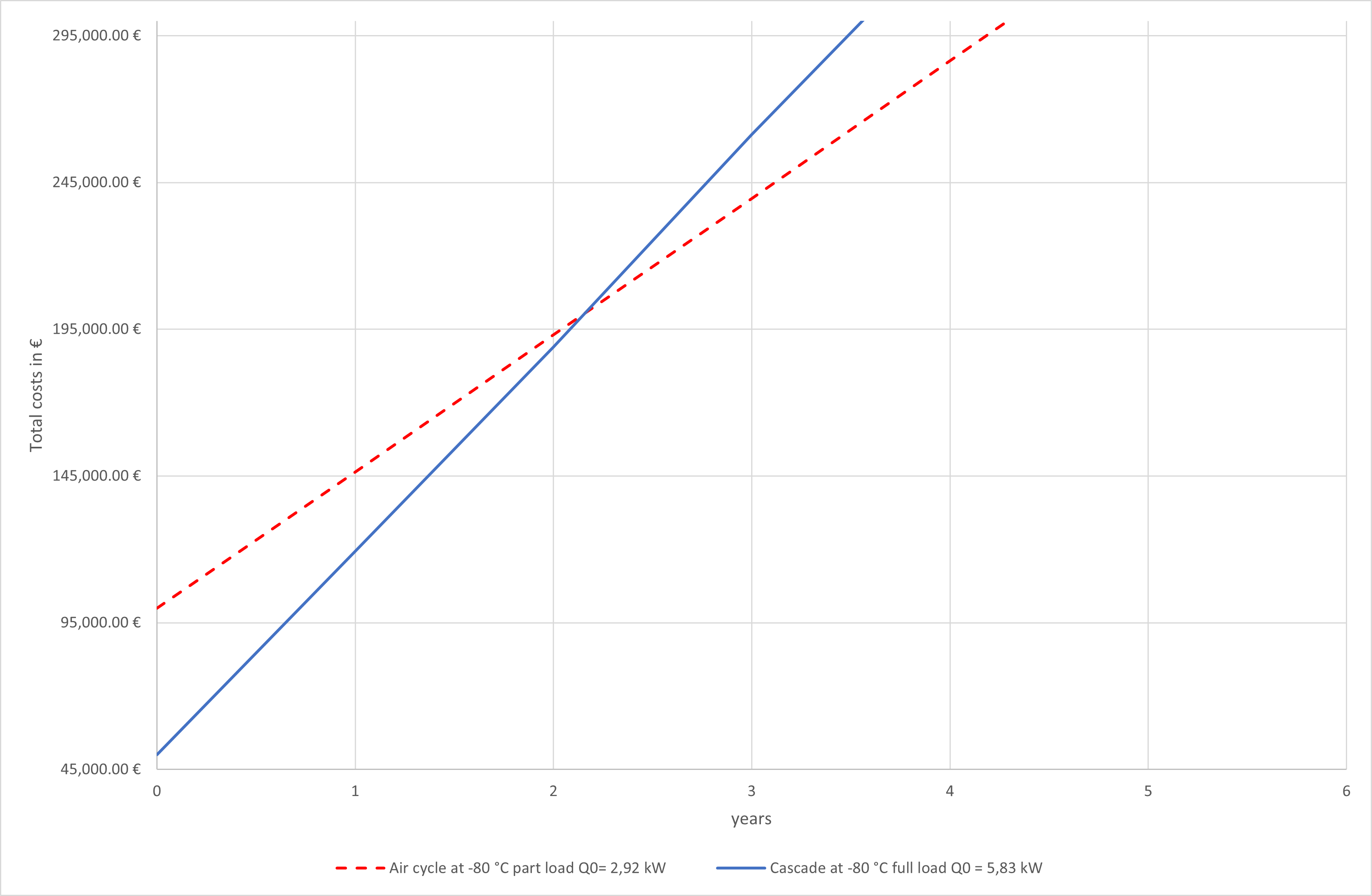

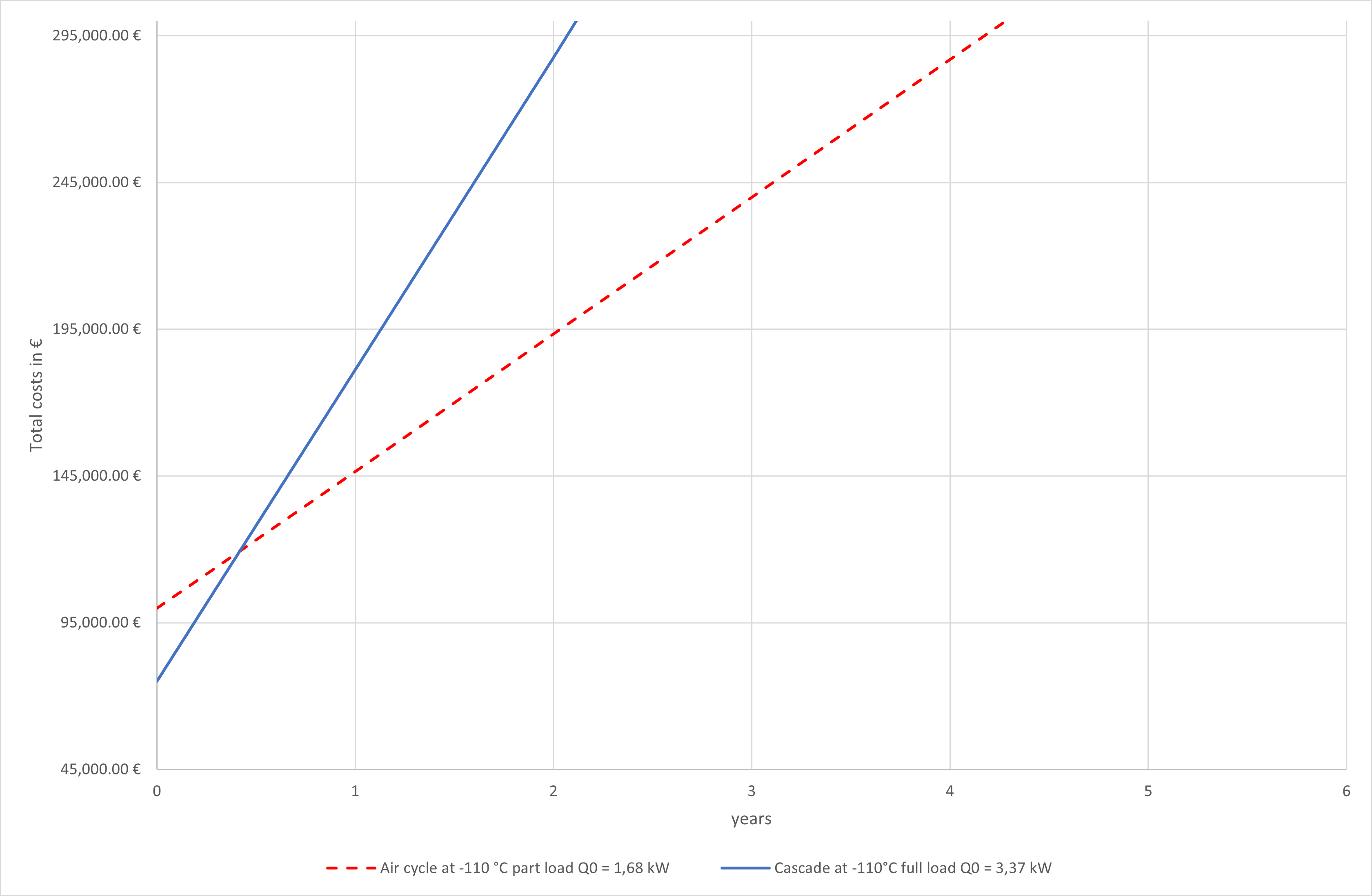

As a result of our calculation from 2018, we were able to compare the total cost of ownership of Mirai Cold system and a vapour compression system. We determined that the cost breakeven point for -80ºC applications was after 3 years and 3 months. For -110ºC the breakeven point was after 9 months. That means that after this period the customer would start saving money by choosing our technology rather than vapour compression systems with environment harming refrigerants (R404A, R23 and R14) .

However, in the face of the recent energy crisis, the costs of electricity have increased dramatically, and with that the cost burden of inefficient systems. This dramatic increased has motivated us to recalculate the total cost of ownership of Mirai air cycle technology and vapour compression cycle for ULT applications. The results were stunning!

Analysis Presumptions

Following characteristics were established for each refrigeration system to define the typical system:

- The typical vapor compression system is defined as the fixed speed with gas-bypass control

→ vapor compression results are represented only by full load results

- All MIRAI Cold machines are equipped with frequency inverter as standard

→ air cycle results are represented by part load results

Considered costs were defined as following:

- The initial cost is the combination of data and estimation*

- Running costs are measured data**

- Maintenance costs are the combination of data and estimation***

* Average current cost was considered for vapor compression systems based on older equipment cost

** Current EU average prices for electricity used

*** Only estimation can be used for vapor compression systems maintenance in the future with increase prices of refrigerants

As you can see the break-even point for –80ºC is 2 years and 3 months and total cost savings for 10 years could be more than 100.000 euro.

For –110ºC applications even break point with current prices for energy is less then 6 month and total saving could be more than 300.000 euro for 10 years.

Calculation could change from region to region, depends on prices in your country but situation is staying on. For long term projects technologies with high energy efficiency class are more attractive.

Also, we have to consider that refrigerant with high level of GWP and ODP under pressure by law regulations. That the one of Mirai key benefits – natural and free refrigerant – AIR.

Discussion of Results

The main difference in the break-even point for both analysed temperatures is caused by the different number of cascades. The relatively cheaper option of two-stage cascade makes the initial advantage for the compressor system. On the other hand, the cost of the additional cascade and running costs quickly shows the supreme performance of the air cycle at -110 °C. This shows a simple fact – the lower the temperature the faster return of the investment. Also playing a significant role are increasing prices of energies, refrigerants, and labour creating further disadvantages for cascade systems.

All this is possible because MIRAI Cold refrigeration machines are developed and designed to change the ultra-low temperature refrigeration market for the better bringing benefits such as:

- Air as a refrigerant – free of charge, available, natural, not bound by regulations

- The safest solution on the market – low pressures, no chemicals

- Operates between -40 °C and -130 °C with maximal temperature accuracy and uniformity

- Highly efficient, economical in use, technologically advanced

- No need for defrosting procedures – continuous cooling operation, continuous humidity extraction

- Easy installation and serviceability

- Very low maintenance compared to conventional technology

Note: Break-even point represents model scenario upon specified conditions and real-life values may differ due to factors unable to predict.