Vacuum drying technique

Vacuum drying is an innovative and vital technique widely used in various industries for efficiently drying materials. It operates under the principle of using lower pressure to reduce the boiling point of water, thereby accelerating moisture removal from sensitive materials. This process is not only efficient but also controlled and precise. This comprehensive article delves into the intricate world of vacuum drying, elucidating its fundamental principles, key advantages, historical evolution, and the pioneering technologies of Mirai Intex in this rapidly advancing field.

Definition of drying vacuum and its main characteristics

Vacuum drying occurs under reduced air pressure, lowering the boiling point of water and allowing for lower-temperature drying, beneficial for heat-sensitive products. This method is characterized by efficient moisture removal, preservation of material properties, and diverse industrial applications.

Brief history of development of drying vacuum

Vacuum drying's history showcases human innovation and progress. Initially a basic method for food preservation, it has become a complex process used across industries. Modern vacuum dryers, integrating advanced techniques like centrifugation and freeze-drying, have greatly improved drying efficiency and effectiveness, reflecting the continuous pursuit of better moisture removal while preserving product quality.

Principles of drying vacuum operation

Main components of drying vacuum plant

- The Drying Chamber-Central to the Process. At the core of every vacuum drying system is the chamber. This pivotal component is where the magic of the drying process unfolds. It's a carefully designed space where items are placed for drying, engineered to ensure uniformity and efficiency in the drying procedure.

- The Role of the Heat Source- Energy for Moisture Evaporation. Integral to the process is the heat source. This crucial element provides the energy required for the evaporation of moisture. What's noteworthy is the adaptability of the heat source to different materials, ensuring that each type of material receives the precise amount of energy needed for effective drying without causing damage.

- The Vacuum System- Creating an Optimal Environment. Another key player in this setup is the vacuum system. Its primary function is to establish and sustain a low-pressure environment within the drying chamber. This reduced pressure is essential as it lowers the boiling point of water, facilitating quicker and more efficient moisture removal from the materials being dried.

- The Condenser- Capturing and Removing Moisture. Lastly, the condenser is a critical component that often doesn't get the limelight it deserves. Its role is to capture and remove the moisture that has been evaporated from the materials. Located within the system, it efficiently condenses the moisture-laden air, ensuring that the drying process is clean and effective."

Methods of vacuum drying

- Tray Vacuum Dryers- Flexibility in Batch Processing. A common and highly versatile method in vacuum drying is the use of tray vacuum dryers. These are particularly favored for their flexibility in batch processing applications. The design of these dryers allows for the easy loading and unloading of materials, making them a popular choice in industries where different batches of products are processed regularly. They are widely employed in the pharmaceutical and food industries due to their ability to handle a variety of materials with care, ensuring quality and consistency in the drying process.

- Microwave Vacuum Dryers- Speed and Uniformity. Another innovative approach in vacuum drying is the use of microwave vacuum dryers. These systems harness the power of microwaves to provide rapid and uniform drying. This method is especially beneficial when dealing with products that are sensitive to heat or require a quick drying process. Microwave vacuum dryers are known for their efficiency in energy use and their ability to evenly dry products, making them suitable for a wide range of applications across various industries.

- Freeze-Drying (Lyophilization)- Preserving Delicate Products. Lastly, freeze-drying, also known as lyophilization, represents a more specialized form of vacuum drying. This technique involves initially freezing the product and then drying it under a vacuum. The process is particularly ideal for delicate and high-value products such as pharmaceuticals, nutraceuticals, and certain food products. By freezing the product first, lyophilization helps to preserve the structural integrity and retains the nutritional and sensory qualities of the product. It's a preferred method for products that are heat-sensitive or need to maintain a specific structure post-drying.

Advantages and disadvantages of drying vacuum

Advantages of Vacuum Drying

Vacuum drying is key for preserving product quality, employing low-temperature processing that protects heat-sensitive items, maintaining their flavor, color, and nutritional value, crucial in industries like pharmaceuticals and food. It enhances efficiency, drying faster than traditional methods due to lower boiling points, leading to higher productivity. Additionally, it conserves energy by operating at lower temperatures, aligning with environmental sustainability goals and reducing the carbon footprint.

Disadvantages of Vacuum Drying

Vacuum drying systems, with their advanced technology, require a higher initial investment than traditional drying equipment. This cost can be prohibitive for small-scale operations or businesses with limited capital. Additionally, these systems are operationally complex, needing skilled handling and precise control, which increases the need for trained personnel and adds to operational costs.

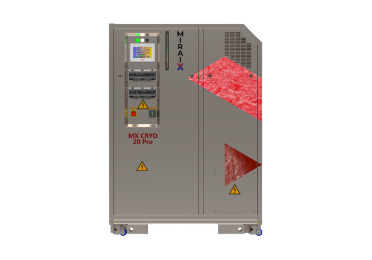

Mirai Intex’s Products and Technologies in Vacuum Drying

Mirai Intex has found applications for its super low temperature machines and vacuum drying technology by offering a range of innovative products and solutions. Our machines are designed not only to ensure efficiency and preserve quality, but are also customized to meet the diverse needs of different industries. Mirai Intex technologies deliver superior results in a wide range of applications, from food processing to industrial manufacturing, with a focus on energy efficiency and product quality. Our commitment to continuous innovation in refrigeration technology not only maximizes efficiency and production convenience, but also significantly reduces costs for manufacturers.

Current Trends in the Vacuum Drying Market

The vacuum drying market is witnessing a significant shift towards more energy-efficient, environmentally friendly, and automated solutions. The integration of smart technologies and automation in vacuum drying systems is becoming increasingly popular, offering enhanced control, improved efficiency, and higher quality outcomes. Innovations in this field are driven by the growing demand for advanced drying solutions that can cater to the complex requirements of modern industries.

Key questions on the topic

What are the applications of vacuum drying?

Vacuum drying is widely used in industries like food processing, pharmaceuticals, and chemicals, offering unique benefits in each:

- In food processing, it's crucial for drying fruits, vegetables, and herbs. This method preserves their nutritional value, taste, color, and aroma, unlike conventional drying, extending shelf life and maintaining consumer appeal.

- In pharmaceuticals, vacuum drying is key for heat-sensitive drugs, preventing degradation and preserving therapeutic properties. This is vital for medications treating chronic or serious conditions.

- In the chemical industry, vacuum drying is essential for drying chemicals without changing their properties. It avoids unwanted reactions or degradation, crucial for producing high-quality chemical products like polymers or reactive agents.

Conclusion

Vacuum drying is a critical component in modern manufacturing and processing industries. It offers unmatched benefits in terms of efficiency, product quality, and energy conservation. Mirai Intex, with its state-of-the-art vacuum drying technologies, is at the forefront of this field, providing innovative solutions that cater to the evolving needs of the market. As the industry continues to evolve, vacuum drying remains a key technology, driving progress and innovation in material processing and preservation.