Air Cycle Technology

The air cycle is widely used in air separation plants as a cooling stage to obtain cryogenic cold, to liquify natural gas, as well as in aircraft air conditioning systems. And we use the air cycle in the production of refrigeration machines. The heart of the system is turbo-module unit developed and manufactured in-house for the most efficient and reliable work.

The technology is based on the heating capability of air during compression and cooling down during expansion. Repetition of compression and expansion cycles allows to reach and maintain ultra-low temperatures down to -160°C.

The technology is based on the heating capability of air during compression and cooling down during expansion. Repetition of compression and expansion cycles allows to reach and maintain ultra-low temperatures down to -160°C.

Reduced power consumption up to

30%

The key feature is the location of turboexpander and compressor are on the same shaft. The energy generated in the expansion process is transferred through the shaft to the compressor, thereby reducing energy consumption by up to 30% compared to vapor compression systems.

Air Bearings

MIRAI Cold machines don’t use traditional friction bushings requiring lubrication. So called “Air bearings” are used instead. Due to the air bearings, the need for complex oil management is eliminated ensuring higher reliability and minimal maintenance.

After the initial start with a low rpm, the shaft is in contact with leaf foil support. With increased rpm, the shaft starts to float on the air cushion created by the increased air pressure from the spinning.

After the initial start with a low rpm, the shaft is in contact with leaf foil support. With increased rpm, the shaft starts to float on the air cushion created by the increased air pressure from the spinning.

Snow Catcher

Humidity Extraction Device HED

Machine operates continuously without defrosting procedures that consume operating cooling power and consume additional energy. Humidity Extraction Device traps ice(humid) particles from air and extracts it automatically out of the cooling space. Installation of the machine is very simple – only a few holes have to be cut in the cold chamber wall to connect MIRAI Cold and Snow Catcher.

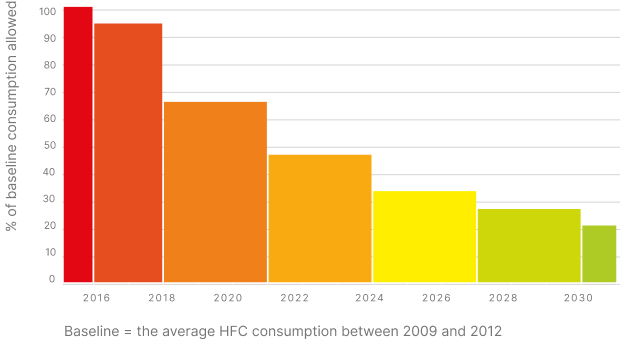

European union F-Gas phase down

The aim of the phased reduction of F-gas emissions is to reduce the usage of HFCs by 79% between 2015 and 2030. We at Mirai support our customers with alternative refrigeration solutions, with a GWP ZERO. Air is not a subject of F-gas regulation and is the best substitute to existing refrigerants and offers full refrigeration, capacity and safety.

Eco-Friendly

- Air as refrigerant

- No need to refilling

- Environmentally friendly

Oil free

- No oil in the system due to air bearings

- Reduced costs

Legislative compliance

- Legislative compliance

- Compliance with all international standards / regulations

Operating stability

- Stable loads on power grid and cooling water even in the most demanding conditions

Safe solution

- No chemically active substances

- No risk of fire or explosion

No vibration or noise

- No vibration or noise

- Turbo module design reduces noise and vibrations

Refrigeration Technology

Comparative table

Air Cycle

Vapor Compression

Liquid Nitrogen

Future Proof

Air as refrigerant

Free refrigerant

GWP = 0

Synthetic refrigerants bans

Natural refrigerants restricted by safety regulations

Transport regulations

Storage regulations

Reliability

Air-bearing compressor

No contacting pairs no wear

Compressor wear

Damage by liquid refrigerant

Damage due to insufficient lubrication

No moving parts

High thermal stress

Safety / Machinery room

Low system pressure from 1 to 10 bar

No need for separate machine room

ATEX directive for respective refrigerants

Gas sensors, ventilation

Vibration damping floor

Gas sensors, ventilation

Space for LN2 storage

Maintenance

Only electrical cabinet filter cartridge exchange

Oil and refrigerant management

Safety valves check

Regular leakage check

Trained staff necessary

LN2 refills

Valve function check

Safety valves check

Part load

Frequency inverter included

RPM of compressor controlled automatically

Depending on system design

Usually start / stop or hot gas bypass

Dosage based

Lifecycle Cost

Almost no maintenance required

No refrigerant purchase and refills

Requires many components

Increasing price of refrigerants

Intensive costly maintenance

High long-term running costs

LN2 to be transported and stored on site