Temperature control system

Temperature control systems are integral to a wide range of applications, ensuring optimal performance, safety, and efficiency. These systems are designed to maintain a desired temperature within a specific range, critical for the functionality of various equipment and processes.

Description of temperature control systems and their equipment needs

Temperature control systems are employed to regulate the temperature in different environments and equipment. They are essential in numerous fields, including manufacturing, healthcare, and domestic settings. Their primary function is to keep the temperature within a specified range to ensure the proper functioning of equipment and processes.

Equipment needing temperature control systems

Temperature control systems are essential in various types of equipment to ensure optimal performance, safety, and longevity. Here’s a more detailed look at different categories of equipment that require such systems:

Industrial machinery

Industrial machinery often generates significant heat during operation. Without proper temperature control, these machines can overheat, leading to reduced efficiency, potential damage, and even safety hazards. Temperature control systems in industrial settings help maintain a stable operating environment, preventing downtime and extending the lifespan of the machinery.

Medical equipment

Medical equipment, such as incubators, MRI machines, and storage units for sensitive materials like vaccines and medications, requires precise temperature control. These systems ensure that the equipment operates within the specified temperature ranges to maintain the integrity and effectiveness of medical treatments and products. Any deviation from the required temperature can compromise patient safety and the efficacy of medical procedures.

HVAC systems

Heating, Ventilation, and Air Conditioning (HVAC) systems are designed to regulate the temperature, humidity, and air quality in residential, commercial, and industrial buildings. Proper temperature control is crucial for creating a comfortable and safe environment for occupants. It also helps in maintaining the structural integrity of the building and the efficient operation of other equipment housed within.

Refrigeration systems

Refrigeration systems, including commercial refrigerators, freezers, and industrial cold storage facilities, are essential for preserving food, pharmaceuticals, and other perishables. Temperature control systems ensure that these items are stored at optimal conditions to prevent spoilage, contamination, and loss of quality. This is particularly important in the food industry, healthcare sector, and logistics.

Electronic devices

Modern electronic devices, such as computers, servers, and communication equipment, generate heat during operation. Overheating can lead to malfunction, data loss, and permanent damage to the components. Temperature control systems, including cooling fans, heat sinks, and liquid cooling systems, help dissipate heat effectively, ensuring that the electronic devices function reliably and have a longer lifespan.

System Types

Temperature control systems vary based on their complexity and the technology they use. They can be broadly classified into several types:

- Simple systems. Simple temperature control systems use basic mechanisms like thermostats and bimetallic strips. These systems are typically found in household applications such as refrigerators and heating systems.

- Complex systems. Complex temperature control systems incorporate advanced technologies like Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems. These are used in industrial applications where precise and reliable control is crucial.

- Wireless systems. Wireless temperature control systems use wireless sensors and controllers to manage temperature. These systems offer flexibility and ease of installation, making them suitable for modern applications where wired connections are impractical.

Main components

Temperature sensors

Temperature sensors are critical for detecting the current temperature. They convert the physical temperature into an electrical signal, which can be processed by the control system. Common types include thermocouples, RTDs (Resistance Temperature Detectors), and thermistors.

Temperature controllers

Temperature controllers receive signals from sensors and compare them to a set point. If there is a discrepancy, the controller takes action to adjust the temperature. Examples include on/off controllers, proportional controllers, and PID (Proportional-Integral-Derivative) controllers.

Actuators

Actuators carry out the commands from the temperature controller. They can include devices such as heaters, coolers, fans, and valves. Actuators directly influence the temperature by adding or removing heat from the system.

Simple systems

In simple temperature control systems, components like a thermostat and a heating element form a basic circuit. The thermostat acts as the temperature controlling device, switching the heating element on or off based on the internal temperature of the space being controlled. This type of system is common in household heating control systems and refrigerators.

Complex systems

Complex temperature control systems integrate PLCs and SCADA systems for advanced temperature management. PLCs provide precise control by executing programmed instructions based on sensor inputs. SCADA systems offer real-time monitoring and control, often used in large-scale industrial applications.

Example: HVAC Systems

In HVAC systems, temperature control is achieved through a combination of sensors, controllers, and actuators. The system monitors the internal temperature and adjusts heating, cooling, and ventilation to maintain a comfortable environment.

Wireless systems

Wireless temperature control systems utilize wireless sensors and controllers, eliminating the need for extensive wiring. These systems are particularly useful in retrofitting older buildings or in applications where wiring is impractical. They offer flexibility and ease of installation while providing accurate temperature control.

Why Control Systems Are Needed

Temperature control systems are essential for maintaining the proper functioning of various applications. They ensure safety, efficiency, and optimal performance by preventing overheating or overcooling.

Examples of Applications

Heating, Ventilation, and Air Conditioning (HVAC) Systems

HVAC systems rely heavily on temperature control to provide comfortable indoor climates. By regulating the temperature, these systems ensure a consistent and comfortable environment while optimizing energy use.

Refrigeration systems

In refrigeration systems, maintaining a specific temperature range is crucial for preserving food and other perishables. Temperature control systems prevent spoilage and ensure the safety of stored items.

Medical facilities

Medical facilities require precise temperature control for the storage of medicines, vaccines, and other sensitive materials. Additionally, equipment such as incubators and surgical rooms depend on accurate temperature management.

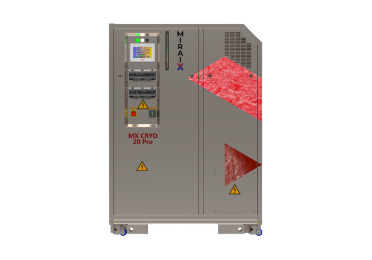

Which MIRAI equipment can use temperature control systems?

Mirai provides a large line of products that have a wide variety of applications. For example, in HVAC applications, the new propane turbo compressor is a great fit, and in refrigeration systems for super low temperatures, Mirai has open and closed cycle machines with over 19 applications and an extensive portfolio of realized projects .

The future of control system development

The development of temperature control systems is continuously evolving, driven by advancements in technology.

Development of IoT (Internet of Things) Technologies

The IoT has revolutionized temperature control by enabling interconnected devices to communicate and collaborate. IoT-based temperature control systems can provide real-time data, predictive maintenance, and remote monitoring, significantly enhancing efficiency and reliability.

Using AI for control

Artificial Intelligence (AI) is poised to play a significant role in the future of temperature control systems. AI algorithms can analyze vast amounts of data to optimize temperature control processes, predict system failures, and reduce energy consumption. By learning from historical data, AI can improve the accuracy and responsiveness of temperature control systems.

Conclusion

Temperature control systems are vital across various applications, from industrial machinery to medical facilities. Understanding what temperature control is and how these systems work can help in selecting the right type for a specific application. With advancements in IoT and AI, the future of temperature control systems promises even greater precision, efficiency, and integration. Whether it’s a simple thermostat in a home or a complex SCADA system in an industrial plant, temperature control remains a critical component of modern technology.