What is a cold trap

In the diverse world of scientific experimentation and industrial processes, the use of a cold trap is indispensable, serving as a critical component in vacuum systems and chemical laboratories. Essentially, a cold trap is a device designed to condense all vapors except the permanent gasses into a liquid or solid state, depending on the temperature of the trap and the vapor pressure of the condensate. This process is particularly beneficial in protecting vacuum pumps from contaminants and moisture, extending the life of the pump and ensuring the purity of the vacuum environment. By utilizing cooling methods such as liquid nitrogen, dry ice, or refrigerated chiller systems,cold traps effectively enhance the efficiency of various applications, from freeze drying and gas chromatography to mass spectrometry and cryostat operations.

The advantages of using a cold trap are manifold, including the prevention of solvent vapor backstreaming, maintaining a cleaner vacuum system, and improving the overall performance of experiments and processes that require precise conditions. Whether employing glassware designed for compatibility with liquid nitrogen or acetone-dry ice slurry for a more accessible cooling option, the integration of a cold trap into laboratory setups and industrial systems signifies a commitment to excellence in achieving reliable and accurate results.

Principle of operation

The principle of operation behind a cold trap hinges on its ability to cool vaporized substances to a point where they revert to a liquid or solid state, thereby preventing these substances from contaminating vacuum systems or damaging sensitive equipment. At its core, the design of cold traps can range from simple glassware to more complex systems equipped with refrigerated chillers or liquid nitrogen reservoirs.

Simple cold traps often consist of a glass condenser connected to a vacuum pump, acting as the first line of defense against vapor intrusion.

Combined cold traps incorporate additional mechanisms like adsorption or cryopreservation, offering an extra layer of protection and efficiency for more demanding applications.

The mechanisms of vapor trapping within these devices are primarily based on condensation and adsorption.

Condensation occurs when vaporized substances come into contact with the cold surface of the trap, transforming back into liquid or solid forms. This method is particularly effective for solvent recovery in processes like freeze drying, gas chromatography, and mass spectrometry and physical vapor deposition where cold traps are also known as meissner coils.

On the other hand, adsorption involves the capture of vapors onto a surface, such as activated charcoal, within the cold trap, which is especially useful for trapping non-condensable gases. Cryopreservation, although less commonly associated with cold traps, can be employed in specialized applications like cryostat operations, where biological samples are preserved at extremely low temperatures. Each of these mechanisms plays a crucial role in the efficient and effective operation of cold traps.

Cooling of cold traps

Cooling of cold traps is a pivotal aspect of their operation, ensuring that they maintain the low temperatures necessary for efficient vapor condensation. There are several types of cooling methodologies employed, each suitable for different applications and requirements. The cooling of the cold traps can be provided with nitrogen, refrigeration systems falling under F-gas regulation, which will soon be banned, or the methods used by Mirai Intex machines such as cooling with air, also nitrogen or HTF(Heat Transfer Fluid).

Traditional cooling agents include liquid nitrogen and dry ice, renowned for their ability to reach extremely low temperatures, making them ideal for liquid nitrogen cold traps used in freeze drying, gas chromatography, and mass spectrometry.

In the realm of engineered cooling solutions, refrigerated chillers,cryo chillers and cryostat systems provide precise temperature control and are capable of sustaining the continuous cooling required for long-term experiments or industrial processes. These systems work by circulating a refrigerant through a condenser, effectively removing heat from the system and maintaining the desired low temperatures within the cold trap.

Which Mirai products can be used in cooling applications

Mirai Intex products, with a focus on innovative and sustainable refrigeration solutions, revolutionize the design and application of cold traps.

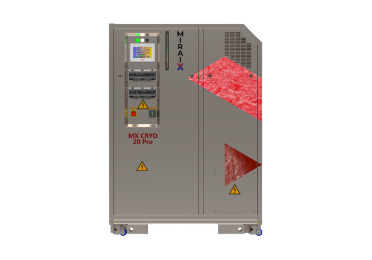

Mirai Intex's air-cycle refrigeration technology, known for its efficiency and environmental friendliness, are seamlessly integrated into cold trap systems. Mirai Intex products such as MIRAI X CRYO is an ideal solution for the PVD market and Closed cycle machines have a great experience in solvent recovery systems and freeze drying. Those machines might offer unparalleled temperature control and stability, essential for precise scientific experiments and industrial processes.

For instance, Mirai Intex refrigeration machines are used in cold traps to provide a sustainable and efficient cooling method, replacing methods using dry ice or banned refrigerants with a more precious,eco-friendly and reliable refrigeration system.

This integration would not only enhance the performance of cold traps in standard applications like gas chromatography but also extend their usability in more sensitive or complex scenarios, such as long-term biological specimen preservation or highly reactive chemical processes.

Furthermore, Mirai Intex's focus on sustainability aligns with the growing demand for environmentally responsible lab and industrial equipment. By using air-cycle technology,the need for hazardous coolants would eliminate, reduce energy consumption, and decrease operational costs. This sustainable approach to cooling could appeal to a wide range of users, from research institutions to pharmaceutical companies, looking to minimize their environmental footprint while maintaining high standards of accuracy and efficiency.

In summary, the potential use of Mirai Intex products in cold traps could signify a significant leap forward in cold trap technology, offering more sustainable, efficient, and precise cooling solutions that meet the evolving needs of scientific research and industrial processes.

Application examples

Cold traps are essential across various applications, safeguarding equipment, ensuring safety, and improving process efficiency. They protect vacuum pumps from vapor and gas damage, crucial for maintaining clean and stable vacuum conditions needed in sophisticated equipment operations like mass spectrometry. Cold traps also play a vital role in capturing toxic and hazardous substances, preventing exposure and enhancing workplace safety. In chemical processes, they facilitate condensate collection, aiding in solvent recovery and reducing environmental impact. Moreover, cold traps are key in gas drying, removing moisture to ensure the accuracy of analytical techniques such as gas chromatography. Whether utilizing liquid nitrogen, dry ice, or refrigerated cooling methods, cold traps prove indispensable in both scientific research and industrial processes, demonstrating their broad utility and effectiveness.

Development prospects

The future of cold traps looks promising with advancements in refrigeration technology, materials science, and eco-friendly cooling solutions like MIRAI Intex products. Innovations may lead to more efficient, durable, and precise cold traps, enhancing their use in freeze drying, gas chromatography, and mass spectrometry, organic solvent recovery and physical vapor deposition.

Developments could include smarter cold traps with automated temperature control and real-time monitoring, improving ease of use and efficiency in protecting vacuum pumps. Additionally, research into natural and alternative refrigerants promises environmentally responsible options with minimal or zero impact. These advancements will not only refine cold trap functionality in existing applications but also unlock new possibilities across scientific and industrial fields, cementing their importance in modern laboratory and production environments.