Cryochillers

In the realm of extreme cold, cryo chillers, also known as cryogenic chillers, stand as a testament to human ingenuity. These devices harness the principles of cryogenics, the study of low temperatures, to achieve temperatures that plunge far below the freezing point. Integral to various fields such as science, medicine, biology, physics, and chemistry, cryo chillers play a pivotal role in both research and industry. Their applications range from cryopreservation in biology to the intricacies of cryo medicine and the rigorous demands of manufacturing and industry.

Operating Principles of Cryocoolers

At the heart of a cryochiller's functionality is the concept of cryo or cryogenic cooling. This process involves the utilization of cryogens, substances used to achieve very low temperatures. Commonly, liquid nitrogen (LN2) is employed due to its ability to reach temperatures as low as -196°C. The cryogenic cooling process in a cryochiller, often referred to as an LN2 cooler or LN2 cooling system, operates on the principle of rapid expansion of gases. As the cryogen transitions from a high-pressure liquid state to a lower pressure gas state, it absorbs heat from its surroundings, thus drastically lowering the temperature.

Main Components of a Cryocooler

A cryochiller, or cryogenic chiller, is an intricate system composed of several essential components, each critical to its efficient operation:

- Cryogenic Chamber. This is the core component where the cooling process takes place. It is typically well-insulated to effectively maintain ultra-low temperatures.

- Cryogen Storage and Delivery System. Often utilizing liquid nitrogen, this system is responsible for storing and delivering the cryogen to the cryogenic chamber.

- Control Systems. Precision control systems are crucial. They regulate the temperature within the cryochiller, ensuring stable and efficient operation.

- Safety Mechanisms. Given the extreme cold and potential hazards associated with cryogenic materials, robust safety features are integral to every cryochiller.

Types of Cryocoolers

Cryocoolers can be classified into several types, each distinct in design and function, catering to different requirements in various fields:

- Closed-Cycle Cryocoolers. These systems recycle the cryogen, making them efficient for applications where continuous supply of cryogen is challenging.

- Open-Cycle Cryocoolers. These rely on a constant supply of cryogen and are often used in situations where a closed-cycle system is not feasible or efficient.

- Specialized Cryocoolers. Some cryocoolers are designed for specific applications, such as those used in space exploration or medical procedures, where unique operational parameters are required.

The selection of a cryochiller type generally depends on the specific needs of the application, whether it is for research, medical purposes, or industrial use.

Application of Cryocoolers

The applications of cryochillers are as diverse as the fields they serve. In the realm of science and research, they are indispensable for experiments requiring low-temperature environments. Cryopreservation, the preservation of cells and tissues at cryogenic temperatures, is a critical application in biology and medicine. In the manufacturing sector, cryochillers aid in processes that require temperature-sensitive handling, such as in the electronics industry. The role of cryochillers in cryomedicine is also noteworthy, where they support various medical procedures and research.

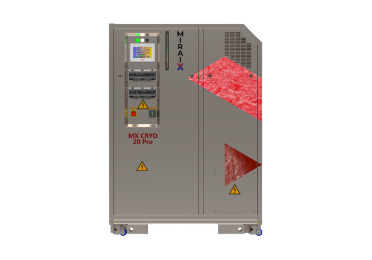

Mirai Intex Cryocoolers

Mirai Intex, a notable player in the cryotechnology field, offers advanced cryochillers that exemplify the cutting-edge of this technology. Their cryocoolers are known for their efficiency, reliability, and adaptability to a range of industrial and research applications. Mirai Intex's commitment to innovation is evident in their continuous improvement of cryocooler designs, aiming to meet the evolving demands of various sectors.

Current Trends in the Development of Cryocoolers

The development of cryocoolers is an ever-evolving landscape, driven by the advancing needs of industry and research. Current trends focus on enhancing efficiency, reducing environmental impact, and improving the scalability of these systems. There's a growing emphasis on developing more compact, yet powerful cryochillers to cater to the space constraints in laboratories and industrial settings. Innovations in cryogenic technology are also steering towards more sustainable solutions, reducing reliance on limited resources like helium and promoting the use of more abundant alternatives like nitrogen.

The Future of Cryochillers

Looking towards the future, the potential of cryochillers continues to expand. One area of growing interest is their application in renewable energy systems. As the world shifts towards cleaner energy sources, the demand for efficient and reliable cryogenic storage solutions is increasing. Cryochillers are poised to play a crucial role in the storage of liquid air and hydrogen, two promising energy carriers.

In the field of space exploration, cryochillers are becoming increasingly important. They are essential for maintaining the low temperatures required for sensitive astronomical instruments and for the preservation of biological samples in space missions. The development of lightweight and robust cryochillers is a key focus in this sector.

The integration of artificial intelligence and machine learning into cryochiller systems is another exciting development. This integration promises to enhance the efficiency and performance of cryochillers by optimizing their operation and predicting maintenance needs. It also opens the door to more sophisticated applications, such as dynamic temperature control in response to real-time data.

In medicine, the advancement of cryomedicine with the aid of cryochillers is leading to breakthroughs in treatments and preservation techniques. Cryochillers are at the forefront of developing better cryopreservation methods for organ transplants, potentially revolutionizing this field. Additionally, their use in cryosurgery for the treatment of certain cancers highlights their critical role in modern medicine.

As technology continues to evolve, the significance of cryochillers in various fields is becoming more pronounced. Their ability to maintain and control extremely low temperatures is not only fascinating from a scientific standpoint but also vital for practical applications. The future of cryotechnology, marked by continuous innovation and improvement, holds promising advancements for the world. As such, cryochillers will remain a critical component in the advancement of various scientific and industrial fields, contributing significantly to the progress of human knowledge and capability.