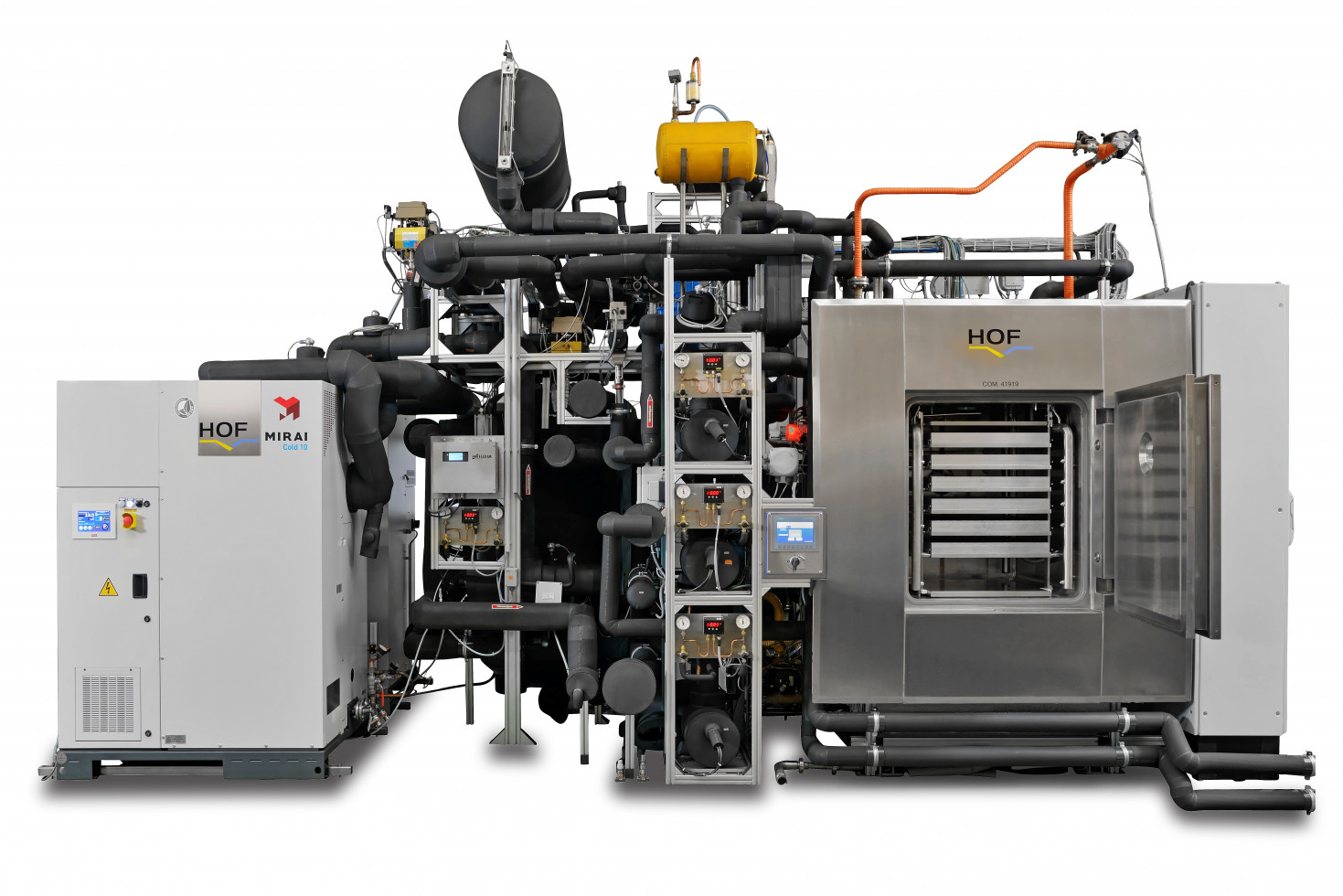

Air cycle technology implemented in a freeze-drying system by HOF

Mirai Intex has introduced its revolutionary MIRAI Cold refrigeration machines to the freeze-drying industry with HOF Sonderanlagen.

MIRAI Cold machines are the most environmentally friendly ultra-low temperature refrigeration solution providing temperature range from -40 °C down to -110°C. Working with natural air as a refrigerant (R729), without oil lubrication due to innovative air bearings and with very stable performance MIRAI Cold could be the ideal refrigeration solution for your application as well.

Application

Freeze-drying, also known as lyophilization, is a water removal process typically used to preserve perishable materials, extend shelf life or make the material more convenient for transport. Freeze-drying works by freezing the material, then reducing the pressure, and adding heat to allow the frozen water in the material to sublimate.

Freeze-drying occurs in three stages: freezing phase, primary drying (sublimation) phase, and secondary drying (adsorption) phase. The freezing phase is the most critical one. Proper freeze-drying can reduce drying time by 30%. In the second phase, the pressure is lowered and heat is added to the material in order for the water to sublimate. The vacuum is introduced to speed up the sublimation. About 95% of the water in the material is removed in this phase. During the third and final phase of the freeze-drying process ionically bound water molecules are removed. By raising the temperature higher than the second stage, the bonds are broken between the material and the water molecules. Most materials can be dried up to 1-5% residual moisture.

Mission

Due to the strategic outlook, HOF Sonderanlagenbau GmbH asked MIRAI Intex to supply their novel natural refrigeration units for their lyophilization system. The F-Gas regulation brings upcoming changes in the near future more ecological and more economical solutions need to be implemented. MIRAI Cold is the ideal representation of these values. Many recent refrigerants have zero ODP (Ozone Depletion Potential) but are still burdened with high GWP (Global Warming Potential). Air does not only have 0 ODP and 0 GWP but is also totally free of charge and absolutely safe to operate.

The assignment for this unique project was to retrofit the existing unit’s refrigeration system with MIRAI Cold refrigeration machines. Proving that not only new state-of-the-art freeze dryers can be paired with Mirai Intex products but also existing equipment could be refurbished and upgraded to make it “future-proof”.

Our partner Refolution GmbH has been providing active engineering support throughout this project. With our joint efforts, the Air cycle refrigeration solution will be on track to take over the Ultra-low temperature refrigeration industry.

Solution

For the technical solution, required by the design of the retrofitted unit, two MIRAI Cold 10 C/W/T units have been selected to provide the necessary cooling power. This is a closed cycle machine equipped with an additional heat exchanger working with primary and secondary loop. The primary loop is the machine’s internal circuit operating with air. The heat transfer is taking place in the heat exchanger intersecting with the secondary loop which operates with heat transfer fluid. For freeze-drying applications, this secondary medium is usually silicone oil which was used in this application as well. MIRAI Cold refrigeration machines are providing oil cooled down to temperatures from -70°C down to -100°C (-94°F to -148°F) in this particular application. The oil reservoir was used to cover the peak load required for cooled oil in this process.

As of today, this retrofitted system has been severely tested and clocked over 5.000 hours of operations and still counting. Preliminary results show up to 15% energy efficiency increase compared to the sister unit which is the identical unit running with the conventional compressor refrigeration system using HFC refrigerants.

Possibilities

There are multiple other options MIRAI Intex can offer for freeze-drying applications.

MIRAI Cold machines can be used in various configurations depending on the end design of the complete lyophilization system. For systems with larger cooling demands multiple MIRAI Cold machines can be run in parallel. The ideal ultra-low temperature refrigeration solution for larger applications would be MIRAI Cold 23 C/W/T. Each application is unique and Mirai Intex is eager to find the perfect ultra-low temperature refrigeration solution for your application.