Features

GAS-DYNAMIC BEARINGS

MIRAI INTEX has developed a new generation of gas-dynamic bearings with millions of operating hours, demonstrating their high efficiency and reliability—these bearings we use in our compressors.

SURGE PROTECTION

To address this issue, MIRAI provides a standard solution in their compressors:

a bypass valve.

This valve is managed by the MIRAI controller and is optional.

ELECTRONIC

Our compressor is certified with an IP54 rating against splashes.

VIBRATION AND NOISE

The MIRAI INTEX compressor does not require balancing or calibration. All parts of the compressor are designed to last the lifetime of the compressor.

Includes only one rotating part - the rotor, that rotates without friction or interaction with other components.

Ensures quiet operation

MIRAI INTEX has developed a new generation of gas-dynamic bearings with millions of operating hours, demonstrating their high efficiency and reliability—these bearings we use in our compressors.

SURGE PROTECTION

To address this issue, MIRAI provides a standard solution in their compressors:

a bypass valve.

This valve is managed by the MIRAI controller and is optional.

ELECTRONIC

Our compressor is certified with an IP54 rating against splashes.

VIBRATION AND NOISE

The MIRAI INTEX compressor does not require balancing or calibration. All parts of the compressor are designed to last the lifetime of the compressor.

Includes only one rotating part - the rotor, that rotates without friction or interaction with other components.

Ensures quiet operation

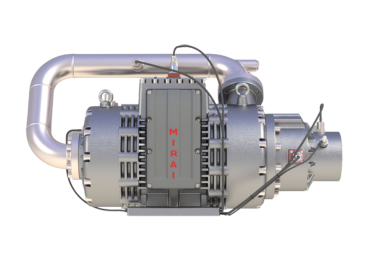

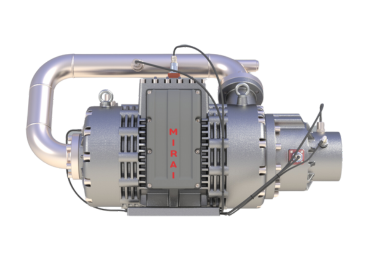

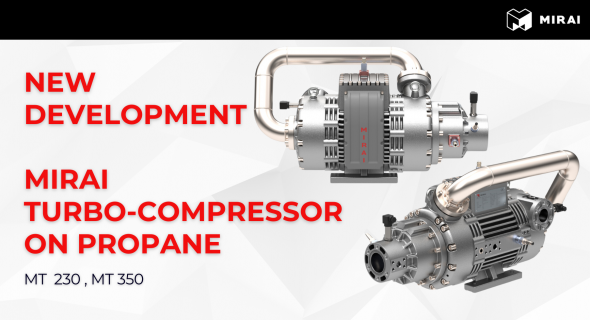

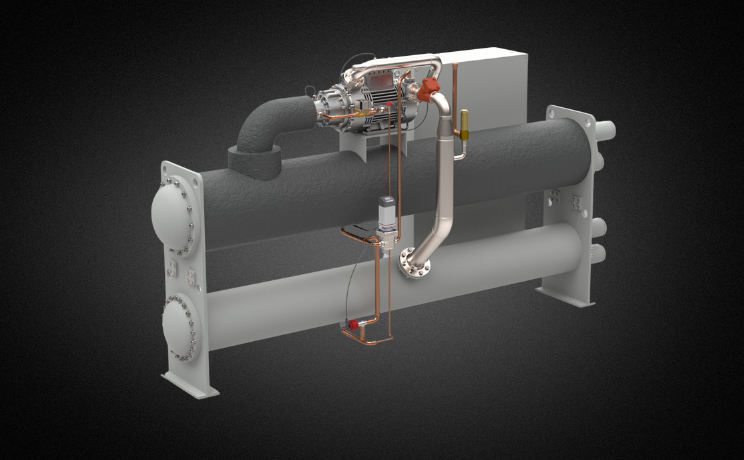

PROPANE TURBO-COMPRESSOR

A modern oil-free, two-stage centrifugal compressor using R290 (propane), delivering high efficiency and performance tailored for industrial refrigeration applications.

PROPANE TURBO-COMPRESSOR

MIRAI Intex presents a revolutionized turbo-compressor, that use R290 (propane). One of the benefits is the soft start of the system - as a standard solution in compressors, that requires low starting current for restarting and keeps the backup systems and generators unloaded.

The MIRAI compressor controller regulates the bypass valve, manages the IGV, and ensures compressor protection and operational safety. The chiller controller sets the power percentage for the MIRAI compressor controller.

Minimal service requirements

The design of the MIRAI compressor is optimized to ensure that all components and sensors are placed externally for easy accessibility. In the event of a breakdown, the only component requiring intervention is the control actuator of IGV. This actuator is strategically positioned to allow access without extensive disassembly of the compressor, merely by removing compressor front section.

Applications

COMPRESSOR APPLICATIONS

Water-cooled Chillers

Compressors in water-cooled chillers are used to compress the refrigerant and keep it circulating in the system. Their main function is to create a pressure difference that allows the refrigerant to absorb heat from the water passing through the evaporator and transfer it to the condenser, where it is then dissipated. This is a key element that ensures efficient cooling of water that is used for climate control in buildings as well as industrial and commercial processes.

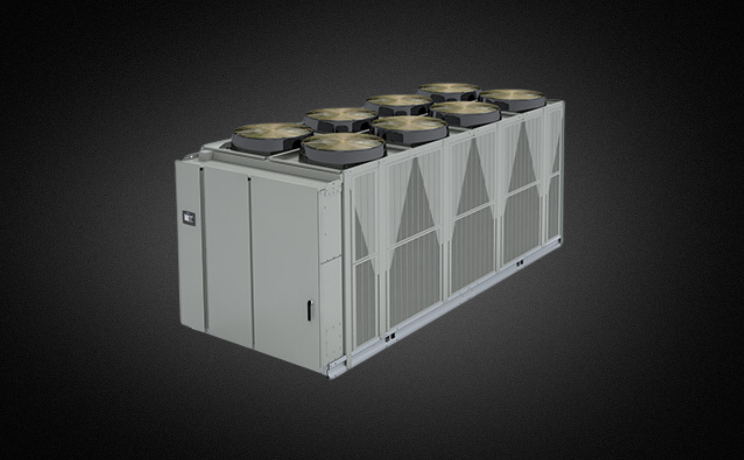

Air-cooled Chillers

Compressors in air-cooled chillers are designed to compress the refrigerant and allow it to circulate through the system. Their main task is to create a pressure difference that allows the refrigerant to absorb heat from the cooled medium in the evaporator and transfer it to the condenser. In the condenser, heat is released into the surrounding air by fans. Compressors are important components that provide efficient cooling of air used in building air conditioning systems, data center cooling, cold storage, as well as in industrial and commercial applications such as shopping centers and medical facilities.